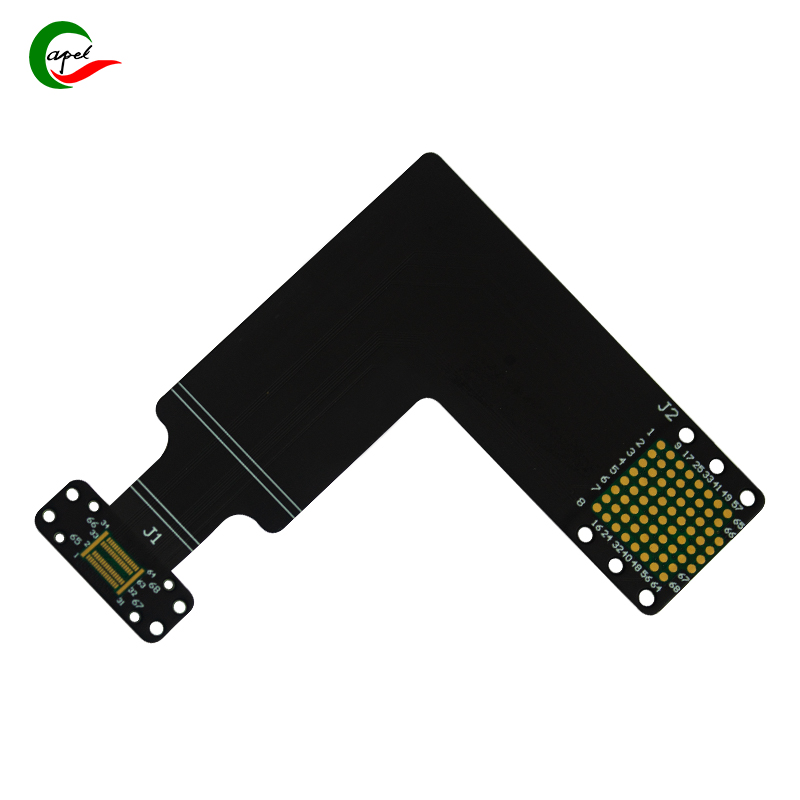

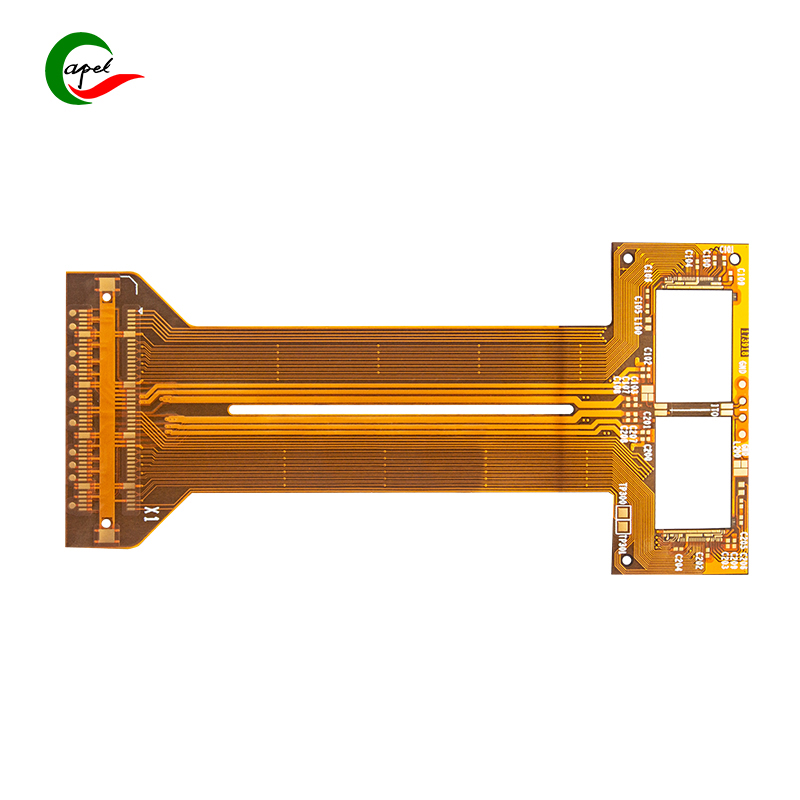

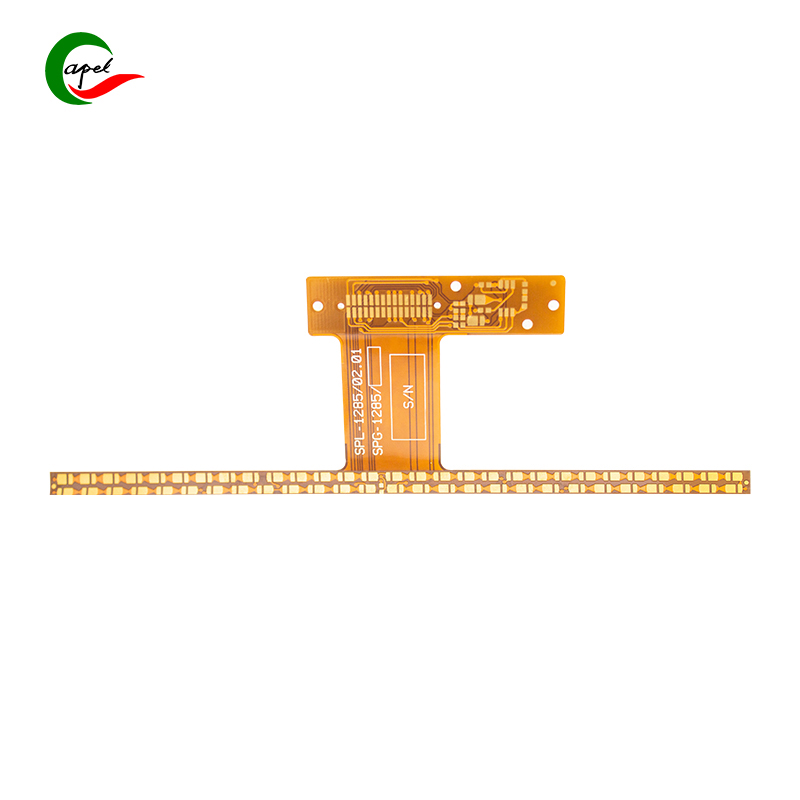

FR4 Daabacan Guddiyada Wareegga Gaarka ah Multilayer Flex PCB Farriinta Taleefanka Casriga ah

Tilmaamid

| Qaybta | Kartida Habraaca | Qaybta | Kartida Habraaca |

| Nooca Wax-soo-saarka | Hal lakab oo FPC / Laba lakab FPC Lakab badan oo FPC / Aluminium PCBs PCB-yada adag-Flex | Lambarka lakabyada | 1-16 lakab FPC 2-16 lakab oo adag-FlexPCB HDI Daabacan Guddiyada Wareegga |

| Cabbirka Wax-soo-saarka ugu badan | Hal lakab oo FPC ah 4000mm Lakabyada Doulbe FPC 1200mm lakabyo badan oo FPC 750mm PCB adag-Flex 750mm | Lakabka dahaadhka ah Dhumucda | 27.5um / 37.5/ 50um / 65/ 75um / 100um / 125um / 150um |

| Dhumucda looxa | FPC 0.06mm - 0.4mm PCB adag-Flex 0.25 - 6.0mm | Dulqaadka PTH Cabbirka | ± 0.075mm |

| Dhamaystir dusha sare | Dahabka Immersion/Immersion Silver/Gold Plating/Tin Plat ing/OSP | Adag | FR4 / PI / PET / SUS / PSA/Alu |

| Cabbirka Orifice Semi-wareega | Ugu yaraan 0.4mm | Meesha khadka ugu yar/ballaca | 0.045mm/0.045mm |

| Dulqaadashada Dhumucda | ±0.03mm | Caqabada | 50Ω-120Ω |

| Dhumucda Foolka Naxaasta | 9um/12um/18um/35um/70um/100um | Caqabada La xakameeyey Dulqaad | ± 10% |

| Dulqaadka NPTH Cabbirka | ±0.05mm | Balaadhka Dheecaanka Min | 0.80mm |

| Min Via Hole | 0.1mm | Fulin Heerka | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Waxaan samaynaa multilayer flex PCB oo leh 15 sano oo waayo-aragnimo ah xirfadeena

3 lakab Flex PCBs

8 PCB-yada adag-Flex

8 lakab HDI Printed Wareegtada

Qalabka Imtixaanka iyo Baaritaanka

Tijaabada Microscope

Kormeerka AOI

Tijaabada 2D

Tijaabada Impedance

Tijaabada RoHS

Baadhitaanka Duulaya

Tijaabada Horizontal

Laacidda Teste

Adeegeena laxanka badan ee PCB Service

. Bixi taageero farsamo iibka ka hor iyo iibinta ka dib;

. Caadiyan ilaa 40 lakab, 1-2maalmood si degdeg ah u rogi kara wax-soo-saar la isku halayn karo, Iibka Qaybaha, Golaha SMT;

. U adeegta labada Aaladaha Caafimaadka, Xakamaynta Warshadaha, Baabuurta, Duulista, Elektarooniga Macmiilka, IOT, UAV, Isgaadhsiinta iwm.

. Kooxahayada injineerada iyo cilmi-baarayaasha waxay u heellan yihiin inay buuxiyaan shuruudahaaga si sax ah oo xirfad leh.

PCB-yada rogrogmi kara ee Multilayer ayaa xalliyay qaar ka mid ah dhibaatooyinka taleefoonnada casriga ah

1. Space-badbaadinta: PCB-da dabacsan ee lakabka badan waxay naqshadayn kartaa oo isku dari kartaa wareegyada adag ee meel xaddidan, taasoo ka dhigaysa taleefannada casriga ah caato iyo is haysta.

2. Daacadnimada ishaarada: Flex PCB waxay yarayn kartaa luminta calaamada iyo faragelinta, hubinta gudbinta xogta xasilloon oo la isku halayn karo inta u dhaxaysa qaybaha.

3. Dabacsanaanta iyo qaloocinta: PCB-yada dabacsan waa la foorarsan karaa, laalaabi karaa ama foorarsan karaa si ay ugu habboonaadaan meelo cidhiidhi ah ama u hoggaansamaan qaabka casriga ah. Dabacsanaantu waxay gacan ka geysataa naqshadeynta guud iyo shaqeynta qalabka.

4. Kalsoonida: PCB-da dabacsan ee lakabka badan waxay yaraynaysaa tirada isku xidhka iyo kala-goysyada alxanka, taas oo wanaajisa isku halaynta, yaraynaysa khatarta guuldarada waxayna hagaajinaysaa tayada guud ee alaabta.

5. Miisaanka la dhimay: PCB-yada dabacsani way ka fudud yihiin PCB-yada adag ee caadiga ah, waxay caawiyaan dhimista miisaanka guud ee talefannada casriga ah, taas oo u sahlaysa isticmaalayaasha inay qaataan oo isticmaalaan.

6. Waaritaanka: PCB-yada dabacsan waxa loogu talagalay in ay u adkaystaan foorarsiga iyo foorarsiga soo noqnoqda iyaga oo aan saamayn ku yeelan waxqabadkooda, taas oo ka dhigaysa in ay aad uga adkaystaan culayska farsamada iyo kor u qaadida cimri dhererka talefannada casriga ah.

PCB-yada dabacsan ee FR4

1. Waa maxay FR4?

FR4 waa laminate ololka oo caadi ahaan loo isticmaalo PCB-yada. Waa walxo fiberglass ah oo leh dahaarka epoxy ololka.

FR4 waxaa lagu yaqaanaa sifooyinkeeda dahaarka korantada oo aad u wanaagsan iyo xoog farsamo oo sarreeya.

2. Waa maxay macnaha "multilayer" marka loo eego PCB-ga dabacsan?

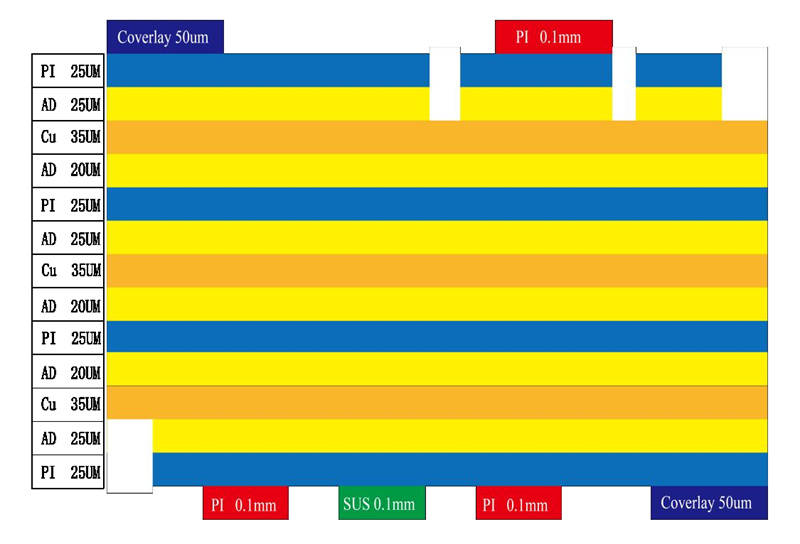

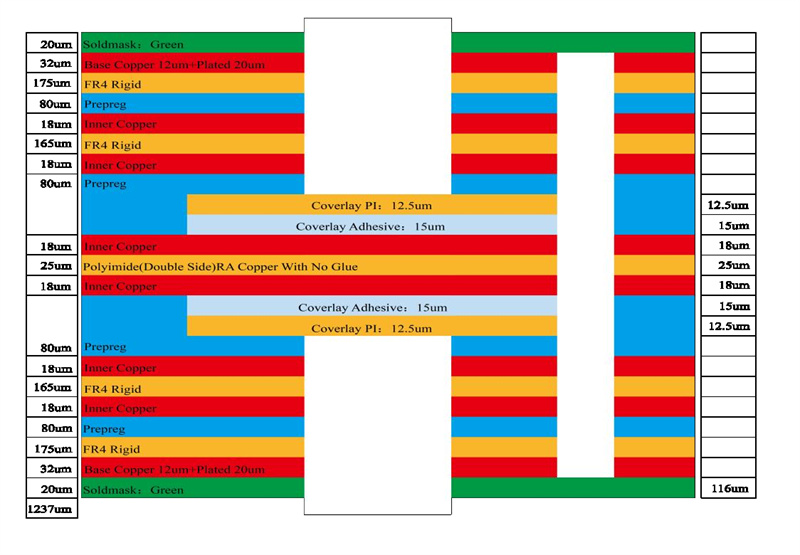

"Multiyer" waxaa loola jeedaa tirada lakabyada ka kooban PCB. PCB-yada dabacsan ee kala duwani waxay ka kooban yihiin laba lakab ama in ka badan oo raad raac ah oo ay kala soocaan lakabyo dahaadh ah, kuwaas oo dhammaantood dabacsanaan xagga dabeecadda ah.

3. Sidee baa looxyada dabacsan ee lakabka badan loogu dabaqi karaa taleefannada casriga ah?

PCB-yada dabacsan ee badan ayaa loo adeegsadaa taleefannada casriga ah si loogu xidho qaybo kala duwan sida microprocessors, chips memory, bandhigay, kamaradaha, dareemayaasha, iyo qaybaha kale ee elegtarooniga ah. Waxay bixiyaan xal kooban oo dabacsan oo isku xidhka qaybahan, awood u siinaya shaqeynta casriga ah.

4. Maxay PCB-yada dabacsan ee lakabka badan uga fiican yihiin PCB-yada adag?

PCB-yada rogrogmi kara ee badan ayaa bixiya faa'iidooyin dhowr ah marka loo eego PCB-yada adag ee casriga ah. Way foorarsan karaan oo laalaabmi karaan si ay ugu habboonaadaan meelo cidhiidhi ah, sida gudaha kiis telefoon ama geesaha qaloocan. Waxay sidoo kale bixiyaan iska caabin wanaagsan oo shoogga iyo gariirka, taasoo ka dhigaysa inay ku habboon yihiin aaladaha la qaadi karo sida taleefannada casriga ah. Intaa waxaa dheer, PCB-yada dabacsan waxay kaa caawinayaan dhimista miisaanka guud ee qalabka.

5. Waa maxay caqabadaha wax soo saarka ee PCB-ga dabacsan ee lakabka badan?

Soo saarista isku-bedelka badan ee PCB-yada ayaa aad uga dhib badan PCB-yada adag. Substrates dabacsan ayaa u baahan in si taxadar leh loo maareeyo inta lagu jiro wax soo saarka si looga hortago burbur. Talaabooyinka wax soo saarka sida lamination waxay u baahan yihiin kontorool sax ah si loo hubiyo isku xidhka saxda ah ee u dhexeeya lakabyada. Intaa waxaa dheer, dulqaadka adag ee naqshadeynta waa in la raaco si loo ilaaliyo daacadnimada calaamadaha loogana fogaado luminta calaamadaha ama hadalka.

6. PCB-yada dabacsan ee lakabka badan ma ka qaalisan yihiin PCB-yada adag?

Multilayer flex PCBs guud ahaan waa ka qaalisan yihiin PCB-yada adag sababtoo ah kakanaanta wax soo saarka ee dheeraadka ah ee ku lug leh iyo agabka gaarka ah ee loo baahan yahay. Si kastaba ha ahaatee, kharashku wuu kala duwanaan karaa iyadoo ku xidhan kakanaanta naqshadaynta, tirada lakabyada iyo caddaymaha loo baahan yahay.

7. Ma la hagaajin karaa FPC-da lakabka badan?

Dayactirka ama dib-u-shaqaynta waxay noqon kartaa mid adag sababtoo ah qaab-dhismeedka kakan iyo dabeecadda dabacsan ee PCB-yada kala duwan. Haddii ay dhacdo cilad ama dhaawac, inta badan way ka kharash badan tahay in la beddelo PCB-ga oo dhan halkii la isku dayi lahaa hagaajin. Si kastaba ha ahaatee, dayactir yar ama dib-u-shaqayn ayaa la samayn karaa iyadoo ku xiran dhibaatada gaarka ah iyo khibradda la heli karo.

8. Ma jiraan wax xaddidaad ama faa'iido darro ah isticmaalka PCB dabacsanaan badan ee casriga ah?

Halka PCB-yada kala duwani ay leeyihiin faa'iidooyin badan, waxay sidoo kale leeyihiin xaddidaadyo. Badana way ka qaalisan yihiin PCB-yada adag. Dabacsanaanta sare ee maaddadu waxay keeni kartaa caqabado inta lagu jiro isku-dhafka, oo u baahan in si taxadar leh loo maareeyo iyo qalab gaar ah. Intaa waxa dheer, habka naqshadaynta iyo tixgalinta qaabaynta ayaa aad ugu adag PCB-yada dabacsan ee lakabyada badan marka la barbar dhigo PCB-yada adag.