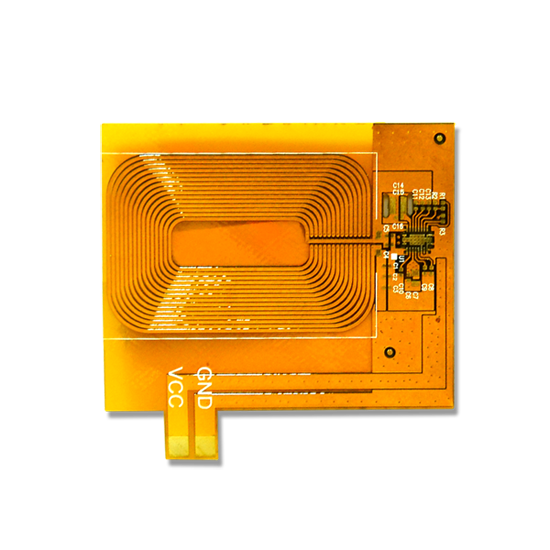

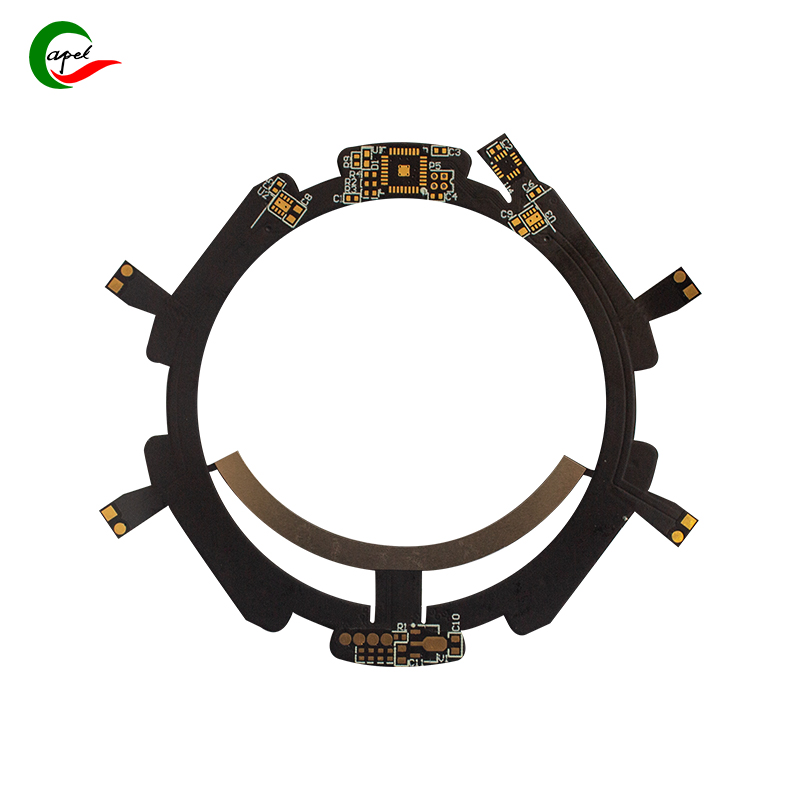

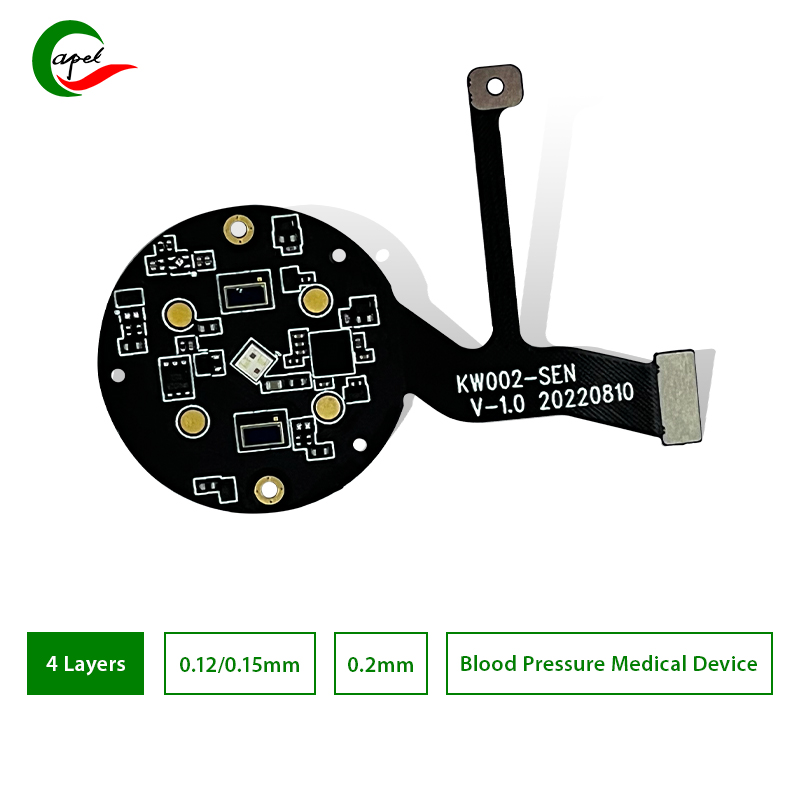

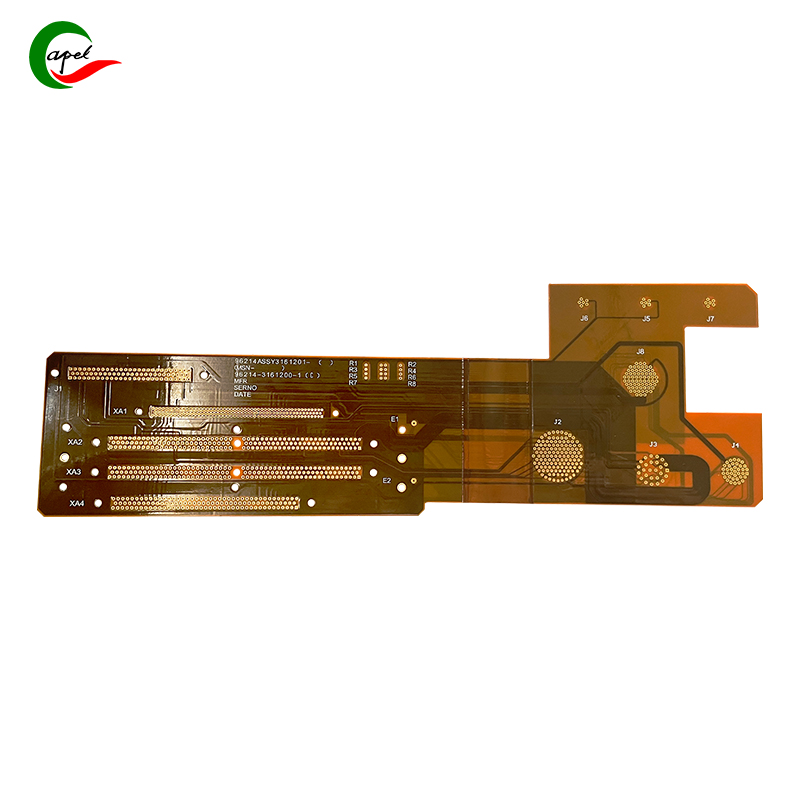

taleefoonka gacanta PCB adag oo adag | smartphone flex PCB wareegga guddiga

Waa maxay dhibaatooyinka ugu adag ee macaamiisha teleefoonka gacanta anteenada fpc looxyada wareegyada dabacsan u baahan yihiin inay xalliyaan?

-Capel oo leh 15 sano oo khibrad farsamo ah

Gudbinta calaamadda soo noqnoqoshada sare: Hubi in guddiga wareeggu uu si wax ku ool ah u gudbin karo calaamadaha soo noqnoqda si looga fogaado hoos u dhaca iyo faragelinta calaamadaha.

Awood ka-hortagga faragelinta: Hubi in guddiga wareegga uusan saameyn ku yeelan aaladaha kale ee elektiroonigga ah ama faragelinta elektromagnetic inta lagu jiro isticmaalka taleefanka gacanta.

Baaxadda iyo miisaanka: Cabbirka iyo miisaanka guddiga wareegga waxay u baahan yihiin in la tixgeliyo si loo hubiyo inay ku habboon tahay shuruudaha naqshadeynta taleefanka.

Dabacsanaanta iyo adkeysiga: Hubi in looxa wareegtada dabacsan aanu si fudud u dhaawacmin marka la leexiyo ama la tuujiyo, oo uu leeyahay waxqabad xasilloon oo muddo dheer ah.

Waxtarka Kharashka: Macaamiisha waxaa laga yaabaa inay la kulmaan caqabado u baahan dheelitirnaanta kharashka iyo waxqabadka.

Wax-soo-saarka: Oo ay ku jiraan wax-soo-saarka dufcaddii hufan iyo hababka isu-ururinta, iyo sidoo kale tignoolajiyada si loo hubiyo tayada guddiga wareegga iyo joogtaynta.

Xulashada agabka: Tixgelinta ayaa loo baahan yahay in la siiyo agab wax qabad sare leh oo ku habboon looxyada wareegyada dabacsan iyo si loo hubiyo isku halaynta silsiladda sahayda. Ilaalinta deegaanka iyo joogteynta: Hubi in habka wax soo saarka ee looxyada wareegyada ay buuxiyaan shuruudaha deegaanka iyo in tuurista looxyada wareegyada qashinka ay gaari karto waara.

Tijaabinta iyo xaqiijinta: Oo ay ku jiraan imtixaan wax ku ool ah iyo xaqiijinta looxyada wareegyada dabacsan si loo hubiyo u hoggaansanaanta qeexitaannada iyo shuruudaha waxqabadka.

Taageerada Farsamada: Macaamiisha waxaa laga yaabaa inay u baahdaan inay bixiyaan taageero farsamo iyo xalal si ay wax uga qabtaan caqabadaha iyo dhibaatooyinka codsiyada la taaban karo.

Gudbinta calaamadda-soo noqnoqoshada sare: Marka la naqshadeynayo anteenooyinka PCB PCB dabacsan, injineeradu waxay isticmaali doonaan mabaadi'da naqshadeynta caadiga ah ee xadadka gudbinta-sare, sida khadadka microstrip. Iyada oo la adeegsanayo is-waafajinta sifada ku habboon iyo naqshadaynta fiilooyinka, hubi in calaamadaha soo noqnoqda ee ugu sarreeya lagu gudbin karo guddiga wareegga iyada oo yareyneysa. Injineerada ayaa isticmaali doona softiweerka jilitaanka si ay u sameeyaan falanqaynta soo noqnoqda iyo falanqaynta wakhtiga si loo xaqiijiyo waxqabadka gudbinta calaamadaha. Tusaale ahaan, marka injineeradu naqshadeeyaan looxyada wareegyada dabacsan, waxay wanaajiyaan ballaca khadka, dhererka dielectric, iyo sifooyinka alaabta iyada oo loo marayo falanqaynta jilitaanka si loo hubiyo in waxqabadka gudbinta ee soo noqnoqoshada gaarka ah uu buuxiyo shuruudaha.

Awoodda ka-hortagga faragelinta: Marka la xalliyo dhibaatada ka hortagga faragelinta, injineerada waxay isticmaali doonaan tignoolajiyada sida naqshadaynta gaashaanka iyo farsamaynta siliga dhulka. Marka lagu daro lakabyada gaashaanka ku habboon iyo fiilooyinka dhulka ee anteenada taleefanka gacanta ee dabacsan PCB, faragelinta calaamadaha korantada ee kale ee signalka anteenada taleefanka gacanta ayaa si wax ku ool ah loo dhimi karaa. Injineerada ayaa sidoo kale isticmaali kara jilitaanka iyo cabbirka dhabta ah si loo xaqiijiyo waxqabadka ka-hortagga faragelinta ee guddiga wareegga si loo hubiyo xasilloonideeda iyo isku halaynta. Tusaale ahaan, mashaariicda dhabta ah, injineeradu waxay ku samayn karaan tijaabooyinka ku habboonaanta korantada ee mobilada looxyada wareegyada dabacsan si ay u xaqiijiyaan awoodahooda ka hortagga faragelinta ee deegaanka dhabta ah.

Baaxadda iyo miisaanka: Marka loo samaynayo PCB dabacsan anteenada taleefanka gacanta, injineeradu waxay u baahan yihiin inay tixgeliyaan shuruudaha naqshadaynta taleefanka gacanta oo ay tixgeliyaan xaddidnaanta cabbirka iyo miisaanka. Isticmaalka tignoolajiyada sida substrates dabacsan iyo fiilooyinka wanaagsan, cabbirka iyo miisaanka looxyada wareegyada si wax ku ool ah ayaa loo dhimi karaa. Tusaale ahaan, injineeradu waxay dooran karaan substrate dabacsan oo dhumuc yar leh waxayna si dabacsanaan u dejin karaan wareegyada iyadoo la raacayo shuruudaha naqshadeynta gaarka ah ee anteenooyinka taleefanka gacanta si loo yareeyo xajmiga iyo miisaanka looxa wareegga.

Dabacsanaanta iyo adkeysiga: Si loo hagaajiyo dabacsanaanta iyo adkeysiga looxyada wareegyada dabacsan, injineeradu waxay isticmaali doonaan substrates dabacsan oo horumarsan iyo hababka isku xirka. Tusaale ahaan, dooro walxo dabacsan oo leh sifooyin qalloocan oo wanaagsan oo isticmaal naqshadaha isku xidhka ee ku habboon si aad u hubiso in guddiga wareeggu aanu si fudud u dhaawacmin foorarid joogto ah ama ka saarista. Injineerada ayaa laga yaabaa inay qiimeeyaan dabacsanaanta guddiga iyo cimri dhererka iyagoo isticmaalaya tijaabin tijaabo ah iyo xaqiijinta isku halaynta.

Waxtarka-kharashka: Injineerada waxay wanaajiyaan naqshadeynta iyo xulashada alaabta si ay isugu dheelitiraan qiimaha iyo waxqabadka. Tusaale ahaan, dooro substrates leh waxqabad aad u wanaagsan iyo qiimo dhexdhexaad ah, yareeya isticmaalka walxaha iyada oo loo marayo naqshadaynta fiilooyinka, oo qaado habab wax soo saar oo hufan iyo qalab toos ah si loo horumariyo waxtarka wax soo saarka, si loo yareeyo kharashyada iyada oo la hubinayo waxqabadka. Mashruucyada dhabta ah, injineeradu waxay isticmaali karaan qalabka falanqaynta kharashka, sida DFM (Design for Manufacturing) software, si ay u qiimeeyaan qiimaha waxtarka leh ee xalalka naqshadeynta iyo bixinta macaamiisha xalka ugu fiican.

Wax-soo-saarka: Injineerada waxay u baahan yihiin inay qaabeeyaan wax-soo-saarka ballaaran ee macquulka ah iyo hababka isu-ururinta si loo hubiyo tayada iyo joogtaynta looxyada wareegga. Tusaale ahaan, inta lagu guda jiro habka wax soo saarka, injineeradu waxay isticmaali karaan SMT (Surface Mount Technology) iyo qalabka isku-ururinta si loo hubiyo tayada sare ee wax soo saarka guddiga wareegga. Injineerada ayaa sidoo kale laga yaabaa inay naqshadeeyaan hababka baaritaanka iyo baaritaanka u dhigma si ay si wax ku ool ah ula socdaan tayada looxyada wareegyada oo ay u hubiyaan inay buuxiyeen tilmaamaha.

Xulashada agabka: Injineerada waxay u baahan yihiin inay doortaan agab wax qabad sare leh oo ku habboon anteenada taleefanka gacanta looxyada wareegyada dabacsan oo xaqiijiya isku halaynta silsiladda sahayda. Tusaale ahaan, marka la dooranayo alaabta, injineeradu waxay tixgelin karaan arrimo ay ka mid yihiin dielectric joogto ah, lumis dielectric, iyo foorarsiga sifooyinka substrates dabacsan, oo ay kala xaajoodaan alaab-qeybiyeyaasha si loo hubiyo helitaanka iyo xasiloonida alaabta. Injineerada ayaa laga yaabaa inay sameeyaan tijaabinta walxaha iyo isbarbardhigga si ay u doortaan xalka agabka ugu habboon.

Ilaalinta deegaanka iyo waaritaanka: Injineerada ayaa qaadan doona hababka wax soo saarka deegaanka saaxiibtinimo iyo xulashada walxaha waara si loo hubiyo in habka wax soo saarka ee FPC anteeno dabacsan PCB buuxiyo shuruudaha deegaanka. Tusaale ahaan, tixgeli waxqabadka deegaanka ee agabka inta lagu jiro marxaladda naqshadaynta, dooro agabka u hoggaansamaya awaamiirta RoHS, iyo naqshadaynta hababka wax-soo-saarka dib loo warshadayn karo. Injineerada waxa kale oo laga yaabaa in ay la shaqeeyaan alaab-qeybiyeyaasha si ay u dhisaan nidaamyada silsiladda sahayda ee buuxinaya yoolalka waaritaanka.

Tijaabinta iyo xaqiijinta: Injineerada ayaa ku samayn doona tijaabooyin kala duwan iyo xaqiijinta anteenada taleefanka gacanta Fpc si loo hubiyo inay buuxiyeen shuruudaha iyo shuruudaha waxqabadka. Tusaale ahaan, qalabka tijaabada soo noqnoqda waxaa loo isticmaalaa tijaabinta waxqabadka gudbinta calaamadaha, iyo qalabka tijaabinta ku-habboonaanta korantada waxaa loo isticmaalaa tijaabinta waxqabadka ka-hortagga faragelinta si loo xaqiijiyo waxqabadka guddiga wareegga. Injineerada ayaa sidoo kale isticmaali kara qalabka tijaabinta isku halaynta si ay u xaqiijiyaan adkeysiga iyo xasiloonida looxyada wareegyada.

Taageerada farsamada: Injineerada ayaa bixin doona taageero farsamo iyo xalal xirfadeed marka macaamiishu la kulmaan caqabado codsi oo la taaban karo. Tusaale ahaan, haddii macmiilku la kulmo dhibaato hawleed xagga codsiga anteenada talefoonka gacanta ee looxa wareegyada dabacsan, injineerku waxa laga yaabaa inuu si qoto dheer u falanqeeyo sababta dhibaatada, soo jeediyo qorshe hagaajin, oo uu ku bixiyo taageero iyo caawimo la taaban karo. codsiyada. Injineerada ayaa laga yaabaa inay macaamiisha siiyaan xalal la beegsanayo iyada oo loo marayo habab kala duwan, sida taageerada fiidiyowga fog, hagitaan farsamo goobta, iwm.

Capel PCB dabacsan & Kartida Geedi socodka PCB adag-Flex

| Qaybta | Kartida Habraaca | Qaybta | Kartida Habraaca |

| Nooca Wax-soo-saarka | Hal lakab oo FPC / Laba lakab FPC Lakab badan oo FPC / Aluminium PCBs Adag-Flex PCB | Lambarka lakabyada | 1-30lakabyada FPC 2-32lakabyada Rigid-FlexPCB1-60lakabyo PCB adag HDILooxyada |

| Cabbirka Wax-soo-saarka ugu badan | Hal lakab oo FPC ah 4000mm Laba lakab FPC 1200mm lakabyo badan oo FPC 750mm PCB adag-Flex 750mm | Lakabka dahaadhka ah Dhumucda | 27.5um / 37.5/ 50um / 65/ 75um / 100um / 125um / 150um |

| Dhumucda looxa | FPC 0.06mm - 0.4mm PCB adag-Flex 0.25 - 6.0mm | Dulqaadka PTH Cabbirka | ± 0.075mm |

| Dhamaystir dusha sare | Dahabka Immersion/Immersion Plating Silver/Gold Plating/Tin Plating/OSP | Adag | FR4 / PI / PET / SUS / PSA/Alu |

| Cabbirka Orifice Semi-wareega | Ugu yaraan 0.4mm | Meesha khadka ugu yar/ballaca | 0.045mm/0.045mm |

| Dulqaadashada Dhumucda | ±0.03mm | Caqabada | 50Ω-120Ω |

| Dhumucda Foolka Naxaasta | 9um/12um/18um/35um/70um/100um | Caqabada La xakameeyey Dulqaad | ± 10% |

| Dulqaadka NPTH Cabbirka | ±0.05mm | Balaadhka Dheecaanka Min | 0.80mm |

| Min Via Hole | 0.1mm | Fulin Heerka | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel waxay soo saartaa saxan sare oo sax ah oo adag oo dabacsanaan leh PCB / PCB / HDI PCB dabacsan oo leh 15 sano oo waayo-aragnimo ah xirfadeena

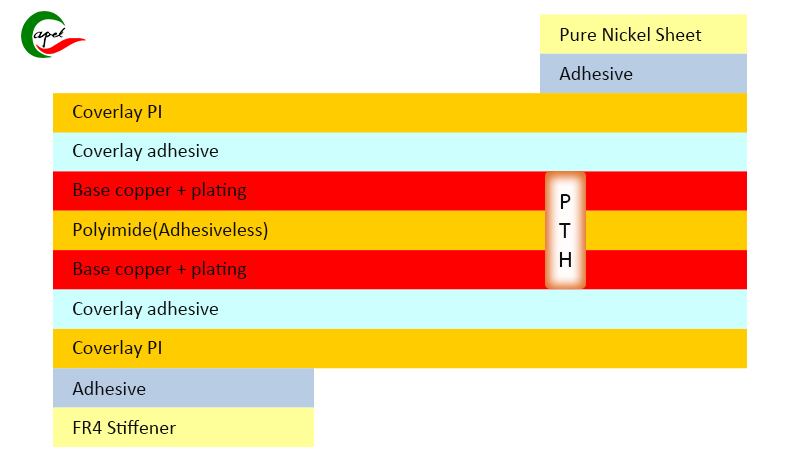

2 Lakabkii Dabacsan ee Guddiyada PCB

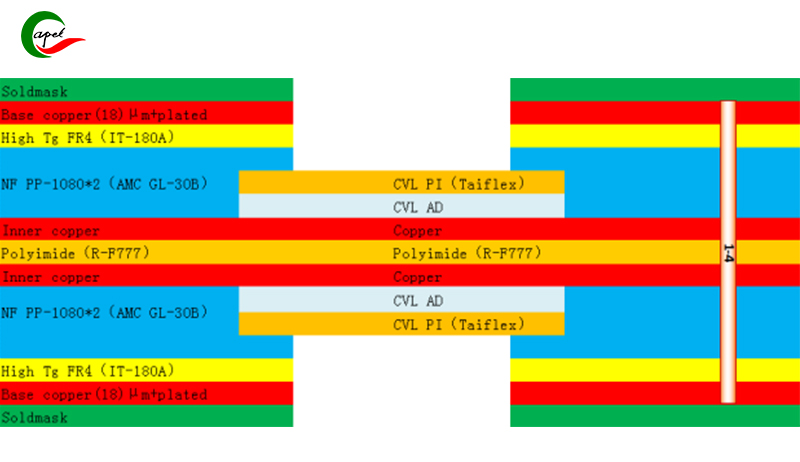

4 Lakabka Adag-Flex PCB Stackup

8 lakab HDI PCBs

Qalabka Imtixaanka iyo Baaritaanka

Tijaabada Microscope

Kormeerka AOI

Tijaabada 2D

Tijaabada Impedance

Tijaabada RoHS

Baadhitaanka Duulaya

Tijaabada Horizontal

Laacidda Teste

Capel waxay siisaa macaamiisha Adeegga PCB ee la habeeyey oo leh 15 sano oo waayo-aragnimo ah

- Lahaanshaha 3warshadaha loogu talagalay PCB Flexible & Rigid-Flex PCB, PCB adag, Golaha DIP/SMT;

- 300+Injineerada Waxay bixiyaan taageero farsamo iibka ka hor iyo iibka ka dib onlayn;

- 1-30lakabyada FPC,2-32Lakabyada Rigid-FlexPCB,1-60lakabyo PCB adag

- Guddiyada HDI, PCB dabacsan (FPC), PCB-yada adag-Flex, PCB-yada badan, PCB-da hal dhinac ah, Guddiyada wareegga laba-geesoodka ah, looxyada godan, PCB Rogers, rf PCB, PCB Core Core, Looxyada Habka Gaarka ah, PCB Ceramic, Aluminium PCB , SMT & PTH Golaha, Adeegga Prototype PCB.

- Bixi24-saacAdeegga soo saarista PCB, Dufcadaha yaryar ee looxyada wareegyada ayaa la geyn doonaa gudaha5-7 maalmood, Wax-soo-saarka ballaaran ee looxyada PCB ayaa la geyn doonaa gudaha2-3 toddobaad;

- Warshadaha aanu u adeegno:Aaladaha Caafimaadka, IOT, TUT, UAV, Aviation, Automotive, Isgaarsiinta, Elektarooniga Macmiilka, Milatariga, Hawada, Xakamaynta Warshadaha, Sirdoonka Artificial, EV, iwm…

- Awood wax-soo-saarkeenna:

Awoodda wax-soo-saarka ee FPC iyo Rigid-Flex PCBs waxay gaari kartaa in ka badan150000sqmbishii,

Awood-soo-saarka PCB ayaa gaari karta80000sqmbishii,

PCB Isku-dubbaridka awoodda150,000,000qaybaha bishii.

- Kooxahayada injineerada iyo cilmi-baarayaasha waxay u heellan yihiin inay buuxiyaan shuruudahaaga si sax ah oo xirfad leh.