3 Lakab HDI PCB dabacsan oo loogu talagalay Macaamiisha Elektarooniga ah

Tilmaamid

| Qaybta | Kartida Habraaca | Qaybta | Kartida Habraaca |

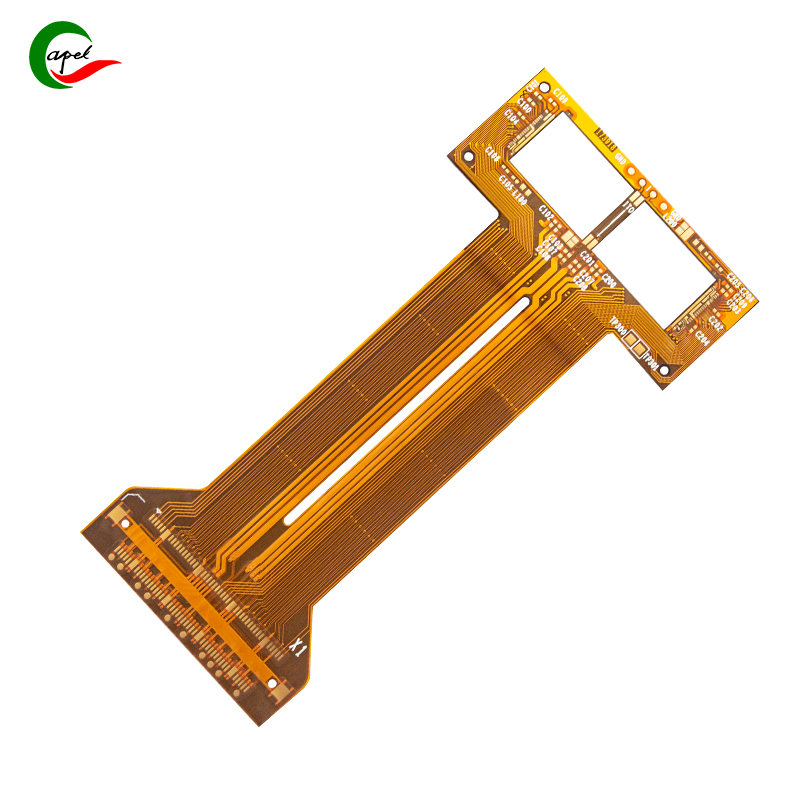

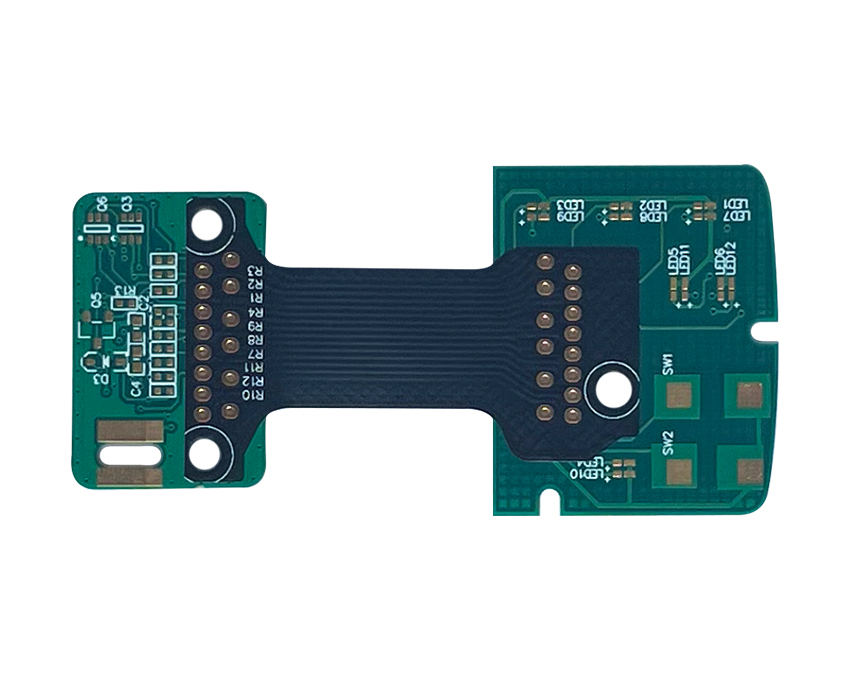

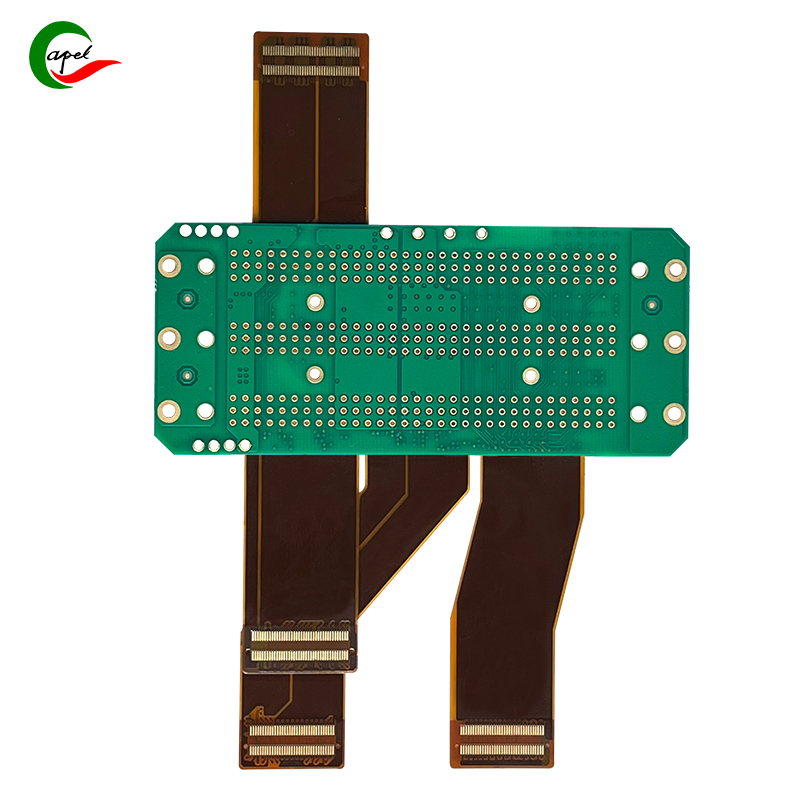

| Nooca Wax-soo-saarka | Hal lakab oo FPC / Laba lakab FPC Lakab badan oo FPC / Aluminium PCBs Adag-Flex PCB | Lambarka lakabyada | 1-16 lakab FPC 2-16 lakab oo adag-FlexPCB Guddiyada HDI |

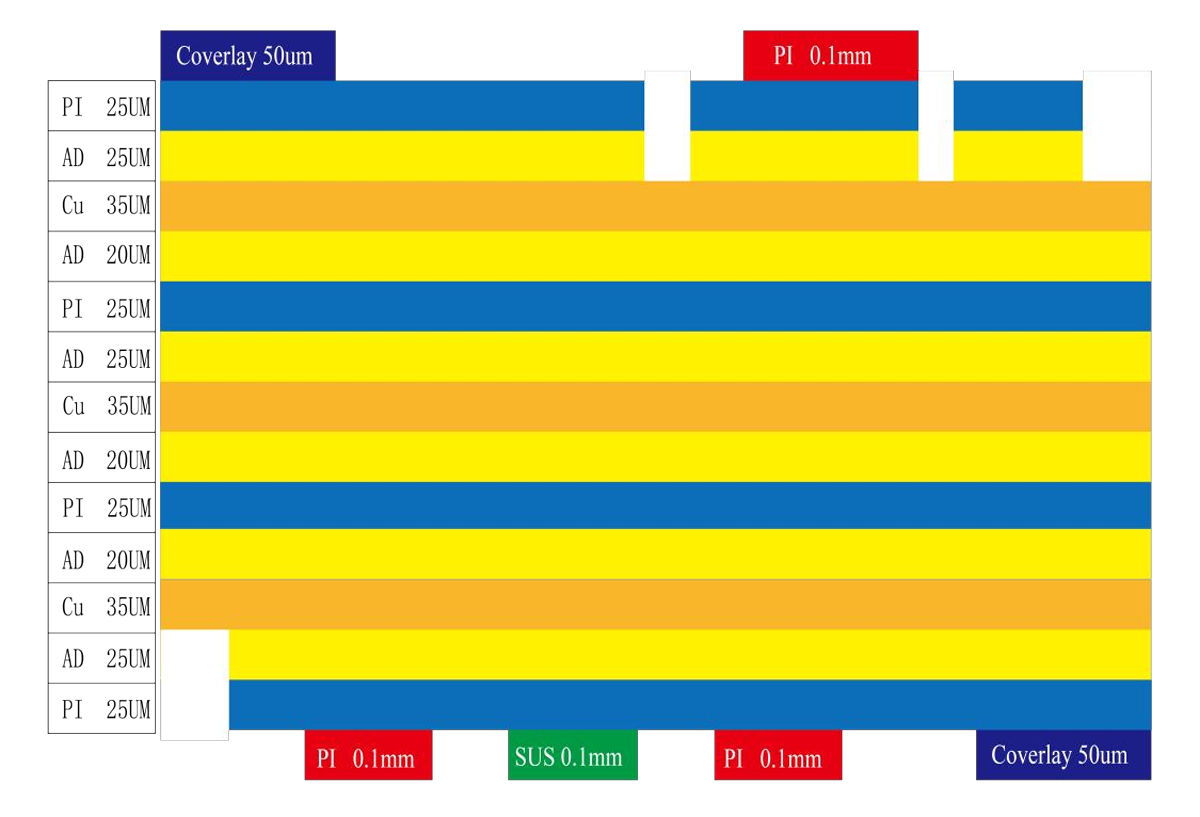

| Cabbirka Wax-soo-saarka ugu badan | Hal lakab oo FPC ah 4000mm Lakabyada Doulbe FPC 1200mm lakabyo badan oo FPC 750mm PCB adag-Flex 750mm | Lakabka dahaadhka ah Dhumucda | 27.5um / 37.5/ 50um / 65/ 75um / 100um / 125um / 150um |

| Dhumucda looxa | FPC 0.06mm - 0.4mm PCB adag-Flex 0.25 - 6.0mm | Dulqaadka PTH Cabbirka | ± 0.075mm |

| Dhamaystir dusha sare | Dahabka Immersion/Immersion Silver/Gold Plating/Tin Plat ing/OSP | Adag | FR4 / PI / PET / SUS / PSA/Alu |

| Cabbirka Orifice Semi-wareega | Ugu yaraan 0.4mm | Meesha khadka ugu yar/ballaca | 0.045mm/0.045mm |

| Dulqaadashada Dhumucda | ±0.03mm | Caqabada | 50Ω-120Ω |

| Dhumucda Foolka Naxaasta | 9um/12um/18um/35um/70um/100um | Caqabada La xakameeyey Dulqaad | ± 10% |

| Dulqaadka NPTH Cabbirka | ±0.05mm | Balaadhka Dheecaanka Min | 0.80mm |

| Min Via Hole | 0.1mm | Fulin Heerka | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Waxaan sameynaa PCB-yada dabacsan oo leh khibrad 15 sano ah oo ku saabsan xirfadeena

Qalabka Imtixaanka iyo Baaritaanka

Tijaabada Microscope

Kormeerka AOI

Tijaabada 2D

Tijaabada Impedance

Tijaabada RoHS

Baadhitaanka Duulaya

Tijaabada Horizontal

Laacidda Teste

Adeegeena Flex PCBs

Bixinta taageero farsamo ka hor iibka iyo iibinta ka dib

.One-Stop sulotion, 1-2days Si degdeg ah u jeedi wax-soosaar la isku halayn karo.

.Waxay u adeegtaa labada Aaladaha Caafimaadka, Xakamaynta Warshadaha, Baabuurta, Duulista, IOT, UAV, Isgaadhsiinta iwm.

.Kooxahayada injineerada iyo cilmi-baarayaasha waxay u heellan yihiin inay buuxiyaan shuruudahaaga si sax ah iyo xirfad.

Flex PCBs FAQ

1. Waa maxay tixgalinta naqshadaynta ee PCB-yada dabacsan?

Marka la naqshadeynayo PCB-yada dabacsan, waxaa muhiim ah in la tixgeliyo arrimo ay ka mid yihiin radius leexashada, tirada lakabyada loo baahan yahay, iyo caqabad kasta oo koronto ah. Waxa kale oo muhiim ah in la doorto substrate-ka saxda ah iyo xabagta si loo hubiyo dabacsanaanta iyo cimri dhererka la rabo.

2. Waa maxay noocyada kala duwan ee PCB-yada dabacsan?

Waxaa jira noocyo badan oo PCB-yada dabacsan oo buuxin kara shuruudaha naqshadaynta ee kala duwan, oo ay ku jiraan:

- PCB-yada dabacsan ee hal dhinac ah: Raadka wax qabad ee hal dhinac iyo substrate dhinaca kale.

- PCB-yada dabacsan ee laba-dhinac leh: Waxaa jira raad-raacyo labada dhinac ah iyo substrate dhexda ku yaal.

- Multilayer flex PCBs: wuxuu leeyahay lakabyo badan oo raad raac ah iyo substrate dahaarka.

- PCB-yada qallafsan: Wuxuu leeyahay isku-darka substrates adag iyo kuwa dabacsan si loo bixiyo adkeysi iyo dabacsanaan.

3. Waa maxay habka tijaabada ee PCB-yada dabacsan?

PCB-yada Flex waxay maraan imtixaano kala duwan inta lagu jiro habka wax soo saarka, oo ay ku jiraan tijaabinta sii wadida korantada, tijaabada kulaylka, iyo tijaabinta makaanikada si loo hubiyo inay buuxiyaan heerarka iyo qeexida loo baahan yahay.

4. Ma la hagaajin karaa Flex PCBs?

PCB-yada Flex waa la hagaajin karaa xaaladaha qaarkood, laakiin tani waxay ku xidhan tahay inta uu le'eg yahay dhaawaca. Burbur yar oo ku yimaadda raadadka wax-qabadka ama substrate-ka waa la hagaajin karaa, laakiin burbur weyn ayaa laga yaabaa inuu u baahdo beddel.

5. Waa maxay arrimaha ay tahay in la tixgeliyo marka la dooranayo soo saaraha PCB-yada flex?

Marka la dooranayo soo saaraha PCB-yada flex, waxaa muhiim ah in la tixgeliyo khibradda, khibradda iyo sumcadda soo saaraha. Waa inaad sidoo kale qiimeysaa tas-hiilaadkooda wax-soo-saarka, qalabka, hababka xakamaynta tayada, iyo adeegyada taageerada macaamiisha. Sidoo kale, waa muhiim inaad hubiso in soo-saaruhu uu buuxin karo shuruudaha naqshadayntaada gaarka ah iyo jadwalka gudbinta.