Degdeg u rog PCB Prototyping 6 Lakab Cufnaan Badan oo Lakab ah oo Dabacsan oo Gawaadhida ah

Tilmaamid

| Qaybta | Kartida Habka | Qaybta | Kartida Habka |

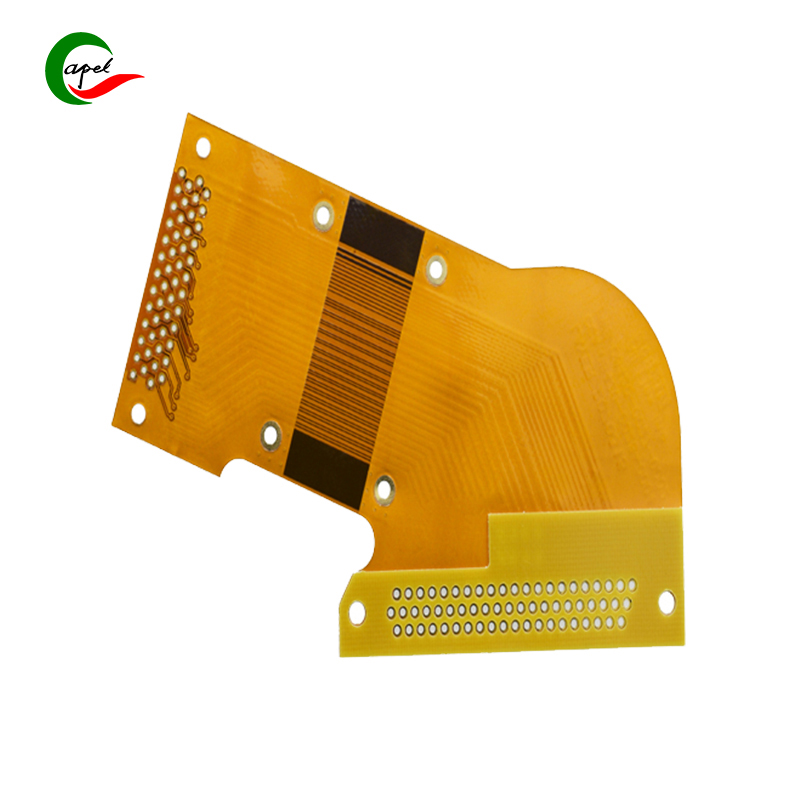

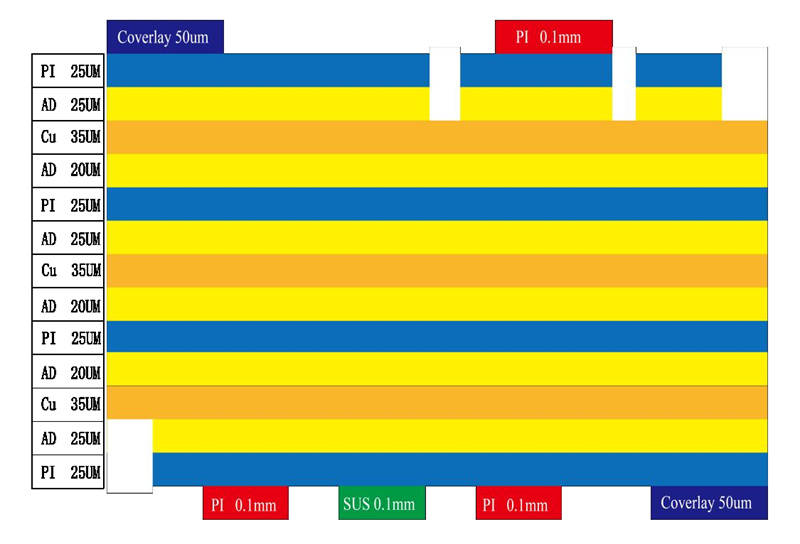

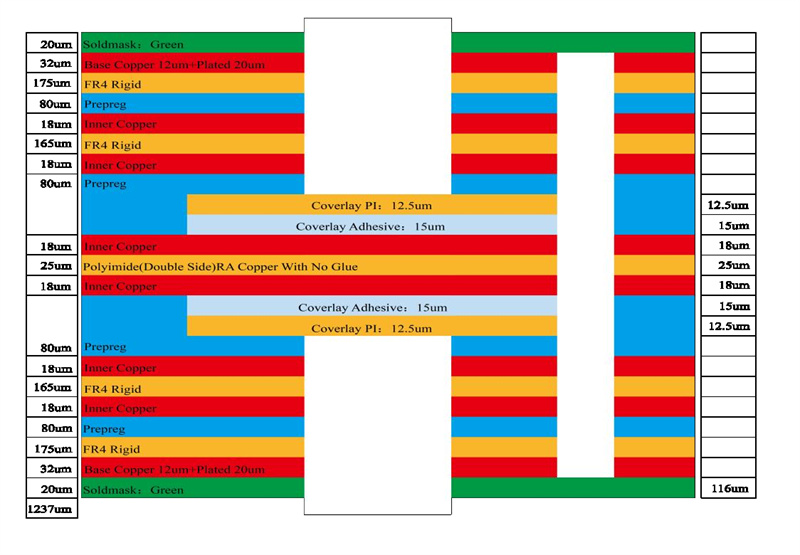

| Nooca Wax-soo-saarka | Hal lakab oo FPC / Laba lakab FPC Lakab badan oo FPC / Aluminium PCBs PCB-yada adag-Flex | Lambarka lakabyada | 1-16 lakab FPC 2-16 lakab oo adag-FlexPCB HDI Printed Circuit Boards |

| Inta ugu badan ee wax soo saarka | Hal lakab oo FPC ah 4000mm Lakabyada Doulbe FPC 1200mm lakabyo badan oo FPC 750mm PCB adag-Flex 750mm | Lakabka dahaadhka ah Dhumucda | 27.5um / 37.5/ 50um / 65/ 75um / 100um / 125um / 150um |

| Dhumucda looxa | FPC 0.06mm - 0.4mm PCB adag-Flex 0.25 - 6.0mm | Dulqaadka PTH Cabbirka | ± 0.075mm |

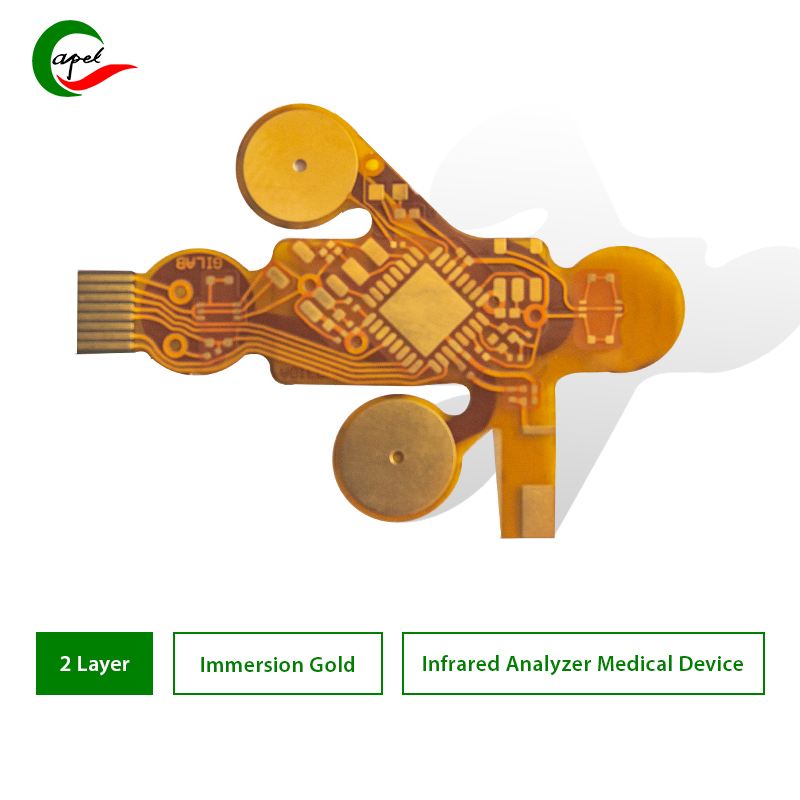

| Dhamaystir dusha sare | Dahabka Immersion/Immersion Silver/Gold Plating/Tin Plat ing/OSP | Adag | FR4 / PI / PET / SUS / PSA/Alu |

| Cabbirka Orifice Semi-wareega | Ugu yaraan 0.4mm | Meesha khadka ugu yar/ballaca | 0.045mm/0.045mm |

| Dulqaadashada Dhumucda | ±0.03mm | Caqabada | 50Ω-120Ω |

| Dhumucda Foolka Naxaasta | 9um/12um/18um/35um/70um/100um | Caqabada La xakameeyey Dulqaad | ± 10% |

| Dulqaadka NPTH Cabbirka | ±0.05mm | Balaadhka Dheecaanka Min | 0.80mm |

| Min Via Hole | 0.1mm | Fulin Heerka | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Waxaan sameynaa loox dabacsan oo lakabyo badan leh oo leh waayo-aragnimo 15 sano ah oo leh xirfadeena

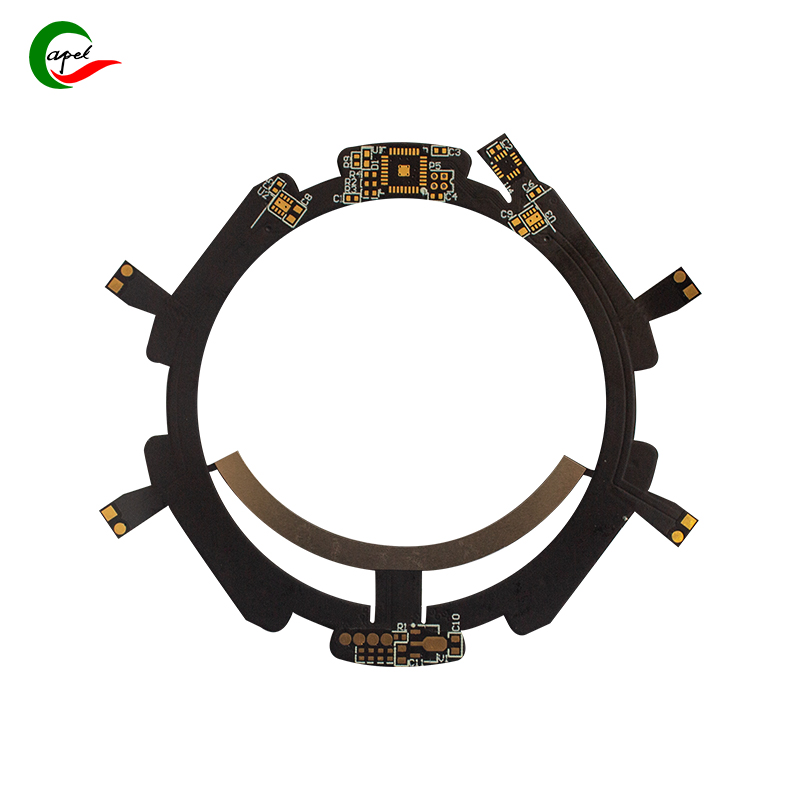

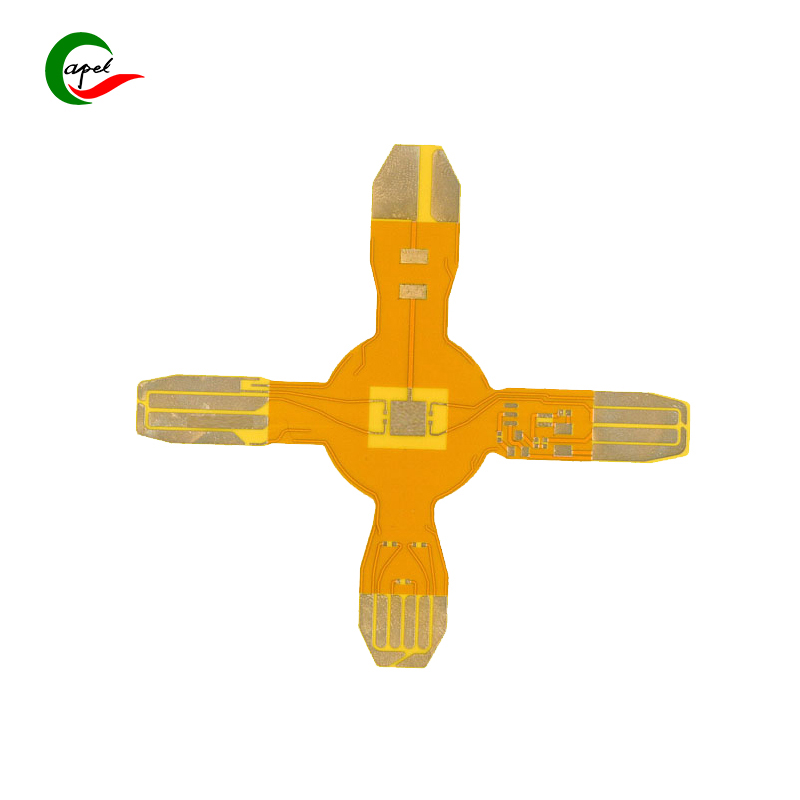

3 lakab Flex PCBs

8 PCB-yada adag-Flex

8 lakab HDI Printed Wareegtada

Qalabka Imtixaanka iyo Kormeerka

Tijaabada Microscope

Kormeerka AOI

Tijaabada 2D

Tijaabada Impedance

Tijaabada RoHS

Baadhitaanka Duulaya

Tijaabada Horizontal

Laacidda Teste

Adeegeena looxyada dabacsan ee lakabka badan

.Bixi taageero farsamo ka hor iibka iyo iibinta ka dib;

.Caadiyan ilaa 40 lakab, 1-2maalmood si degdeg ah u rogi kara wax-soo-saar la isku halayn karo, Iibka Qaybaha, Golaha SMT;

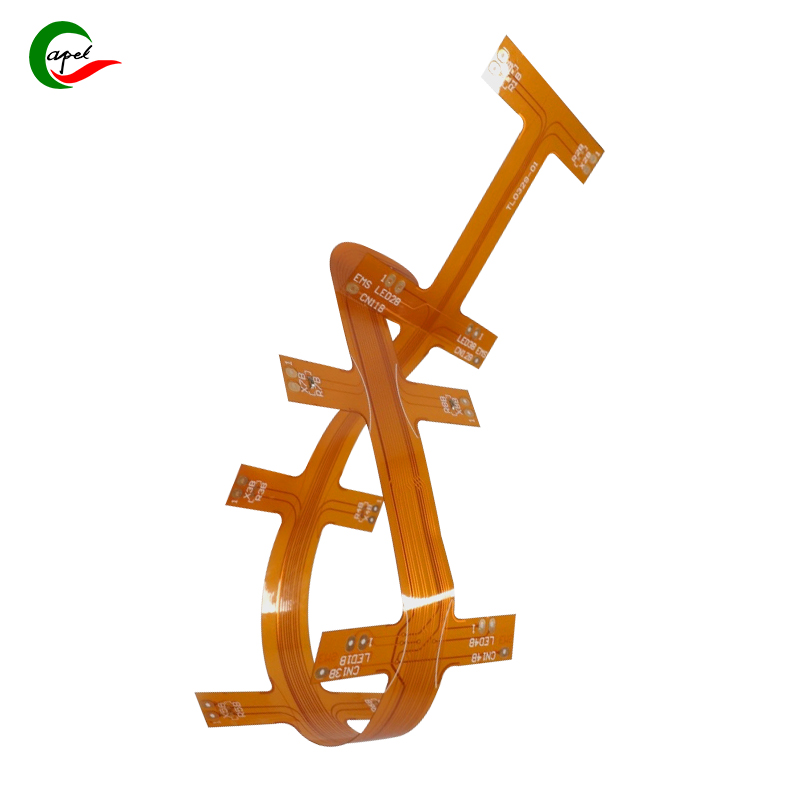

.U adeegta labada Aaladaha Caafimaadka, Xakamaynta Warshadaha, Baabuurta, Duulista, Elektarooniga Macmiilka, IOT, UAV, Isgaadhsiinta iwm.

.Kooxahayada injineerada iyo cilmi-baarayaasha waxay u heellan yihiin inay buuxiyaan shuruudahaaga si sax ah oo xirfad leh.

Waa maxay shuruudaha farsamada ee PCB-yada baabuurta ee looxyada dabacsan ee lakabyada badan?

1. Waarta: PCB-yada baabuurta waa in ay u adkeysan karaan xaaladaha adag ee shaqada ee baabuurka, oo ay ku jiraan isbedbeddelka heerkulka, gariirka, iyo qoyaanka.Waxay ballanqaadayaan nolol adeeg oo dheer iyo xasillooni farsamo oo aad u wanaagsan.

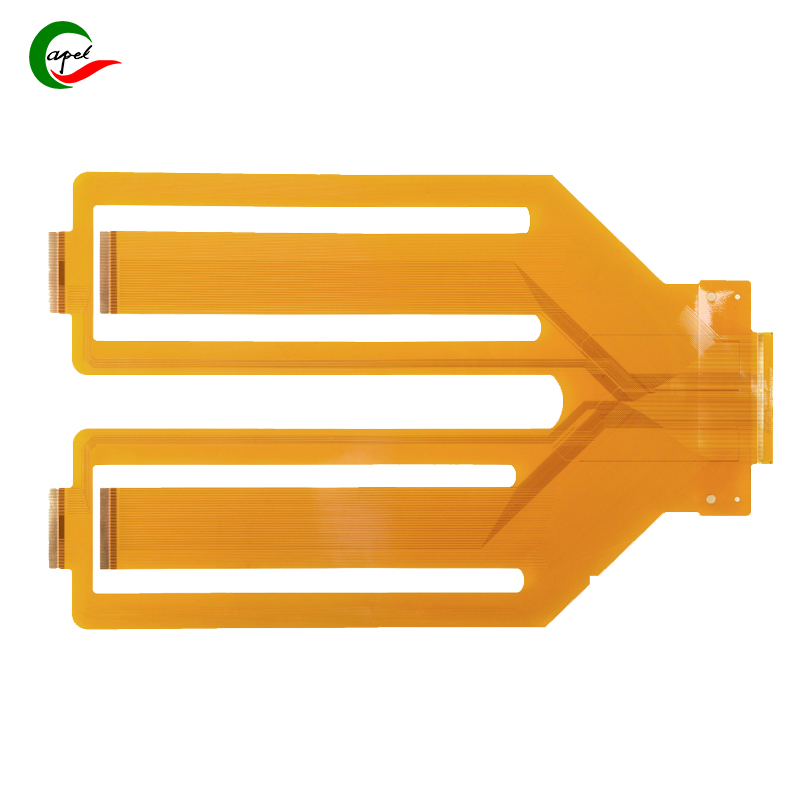

2. Cufnaanta Sare: PCB-da dabacsan ee lakabka badan ayaa u oggolaanaysa isku xirka korantada iyo qaybaha in lagu dhex daro meel bannaan.Naqshadeynta cufnaanta sare waxay awood u siineysaa marin hufan waxayna yareysaa cabbirka PCB-ga, badbaadinta booska qiimaha leh ee gaariga.

3. Dabacsanaanta iyo leexinta: PCB-yada dabacsan si fudud ayaa loo laalaabi karaa, loo leexin karaa ama u laaban karaa si ay ugu habboonaadaan meelo cidhiidhi ah ama u hoggaansamaan qaabka gaadhiga.Waa inay ilaashadaan daacadnimadooda korantada iyo farsamada inta lagu jiro foorarsiga iyo dabacsanaanta soo noqnoqda.

4. daacadnimada isha: Waa in ay yaraataa calaamada luminta ama faragelinta qaylada ee PCB si loo hubiyo xidhiidhka la isku halayn karo ee ka dhexeeya qaybaha kala duwan ee elegtarooniga ah.Shaqaalayso farsamooyin ay ka mid yihiin xakamaynta impedance iyo dhul dhigista saxda ah si aad u ilaaliso daacadnimada calaamadaha.

5. Maaraynta kulaylka: Looxyada wareegga baabuurta waa in ay si wax ku ool ah u baabi'iyaan kulaylka ka dhashay hawlgalka.Farsamooyinka maaraynta kulaylka ee waxtarka leh, sida isticmaalka diyaaradaha naxaasta ah ee saxda ah iyo vias kulaylka, ayaa lagama maarmaan u ah ka hortagga kulaylka iyo hubinta waxqabadka xasilloon.

6. EMI/RFI gaashaandhigga: Si looga hortago faragelinta korantada (EMI) iyo faragelinta soo noqnoqda raadiyaha (RFI), PCB-yada baabuurta waxay u baahan yihiin farsamooyin difaac oo habboon.Tani waxay ku lug leedahay isticmaalka gaashaanka ama diyaaradaha dhulka si loo yareeyo saameynta calaamadaha korantada ee dibadda.

7. Imtixaanka khadka: Naqshadaynta PCB waa in ay fududaysaa tijaabinta iyo kormeerka PCB-ga la isugu keenay.Helitaanka saxda ah ee dhibcaha tijaabada iyo baaritaanka tijaabada waa in la bixiyaa si loo xaqiijiyo tijaabinta saxda ah oo hufan inta lagu jiro wax soo saarka iyo dayactirka.

8. U hoggaansanaanta heerarka baabuurta: Nakhshadeynta iyo soo saarista PCB-yada baabuurta waxay u baahan yihiin inay raacaan heerarka warshadaha baabuurta, sida AEC-Q100 iyo ISO/TS 16949. U hoggaansanaanta heerarkan waxay hubisaa isku halaynta, badbaadada iyo tayada PCBs.

Maxaad ugu baahan tahay-soo-jeedinta PCB Prototyping?

1. Xawaaraha: Prototyping PCB ee degdega ah waxa uu dedejiyaa wareegyada horumarinta alaabta.Waxay kaa caawinaysaa in la dhimo wakhtiga loo baahan yahay in lagu cel-celiyo, la tijaabiyo, oo la hagaajiyo naqshadaha PCB, taasoo awood u siinaysa injineerada inay la kulmaan waqtiyada kama dambaysta ah ee mashruuca ama ay si degdeg ah uga jawaabaan dalabaadka suuqa.

2. Xaqiijinta Naqshadeynta: Prototyping PCB wuxuu u oggolaanayaa injineerada inay xaqiijiyaan shaqeynta, waxqabadka iyo wax soo saarka ee naqshadahooda PCB ka hor intaysan tagin wax soo saar ballaaran.Waxay gacan ka geysataa aqoonsashada iyo xallinta cillad kasta oo naqshadeynta ama fursadaha hagaajinta, badbaadinta waqtiga iyo lacagta mustaqbalka fog.

3. Khatarta la dhimay: Barashada PCB ee degdega ah waxay caawisaa dhimista khataraha la xidhiidha wax-soo-saarka badan ee PCB.Marka la tijaabiyo oo la ansixiyo naqshadaha kooxo yaryar, khaladaad kasta oo iman kara ama arrimo ayaa la qaban karaa goor hore, ka hortagga khaladaadka qaaliga ah iyo dib-u-shaqaynta inta lagu jiro wax-soo-saarka baaxadda leh.

4. Kharashka kaydinta: PCB-ga oo si degdeg ah u habeeya waxa ay si hufan u isticmaali kartaa agabka iyo agabka.Iyaga oo la qabsanaya arrimaha naqshadaynta goor hore oo samaynta hagaajinta lagama maarmaanka ah, injineeradu waxay badbaadin karaan alaabada khasaartay iyo dib u habeynta naqshadeynta ee qaaliga ah.

5. Ka jawaab celinta suuqa: Warshadaha degdega ah, awood u yeelashada in ay si dhakhso ah u horumariso oo ay u soo saarto alaab cusub waxay siin kartaa shirkad faa'iido tartan ah.Prototyping PCB ee degdega ah wuxuu u sahlayaa shirkadaha inay si dhakhso ah uga jawaabaan dalabaadka suuqa, beddelka isbeddelada ama fursadaha cusub, hubinta in la sii daayo alaabta waqtigeeda.

6. Habaynta iyo hal-abuurka: Prototyping-ku waxa uu fududeeyaa habaynta iyo hal-abuurka.Injineerada ayaa sahamin kara fikradaha naqshadeynta cusub, tijaabin karaan astaamo kala duwan, waxayna tijaabin karaan tignoolajiyada horumarsan.Waxay awood u siinaysaa inay riixaan xudduudaha oo ay horumariyaan alaab-goyn.