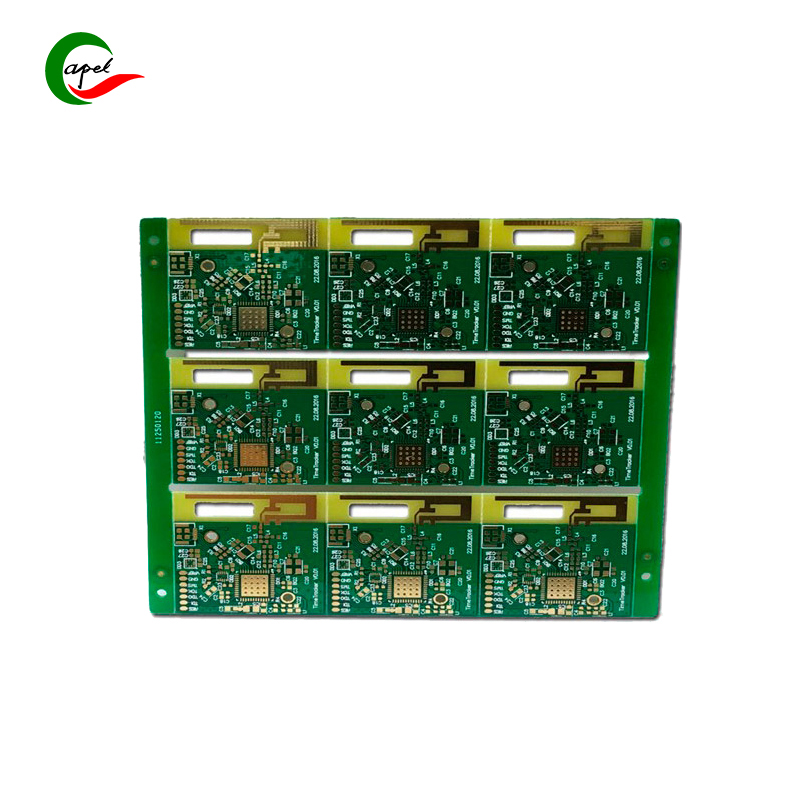

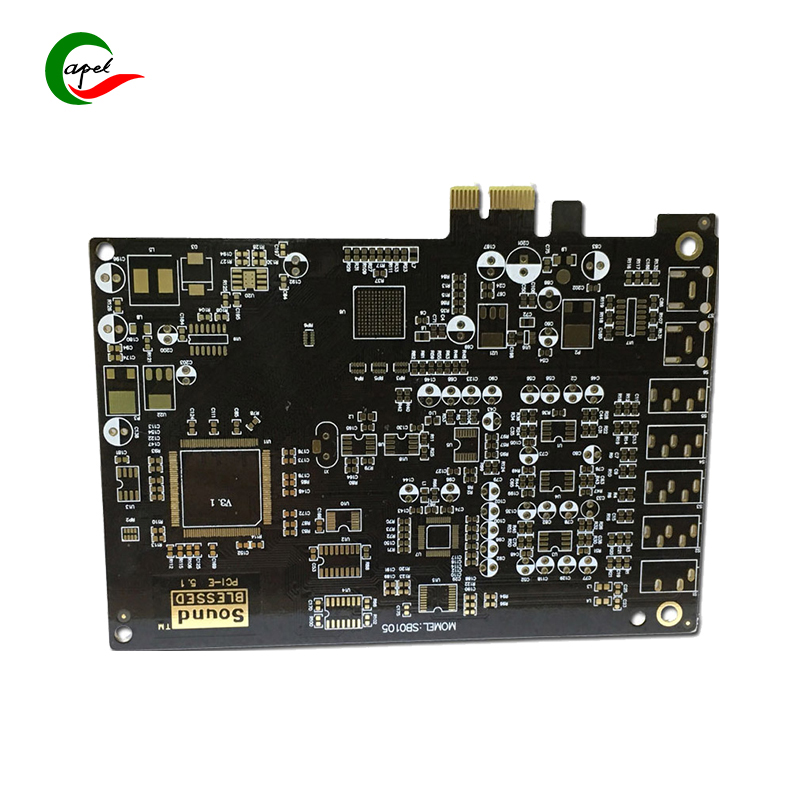

6 Lakabka PCB Wareegga Wareegga Degdegga ah ee Pcb Prototyping Pcb Manufacturer China

Kartida Habka PCB

| Maya | Mashruuca | Tilmaamayaasha farsamada |

| 1 | Lakabka | 1 - 60 (lakab) |

| 2 | Meesha ugu sarraysa | 545 x 622 mm |

| 3 | Dhumucnaanta ugu yar | 4 (lakab) 0.40mm |

| 6 (lakab) 0.60mm | ||

| 8 (lakab) 0.8mm | ||

| 10 (lakab) 1.0mm | ||

| 4 | Balaadhka khadka ugu yar | 0.0762mm |

| 5 | Kala dheeraynta ugu yar | 0.0762mm |

| 6 | Daloollada ugu yar ee farsamada | 0.15mm |

| 7 | Dhumucdiisuna waxay tahay derbi dalool | 0.015mm |

| 8 | Dulqaadka daloolka birta ah | ±0.05mm |

| 9 | Dulqaad aan bir lahayn | ± 0.025mm |

| 10 | Dulqaadashada | ±0.05mm |

| 11 | Dulqaadka cabbirka | ± 0.076mm |

| 12 | Buundada alxanka ugu yar | 0.08mm |

| 13 | Iska caabin dahaarka | 1E+12Ω (caadi) |

| 14 | Saamiga dhumucda saxanka | 1:10 |

| 15 | Naxdinta kulaylka | 288 ℃ (4 jeer 10 ilbiriqsi gudahood) |

| 16 | Qallooc iyo qaloocsanaan | ≤0.7% |

| 17 | Awood ka-hortagga korontada | 1.3KV/mm |

| 18 | Xoogga ka-hortagga | 1.4N/mm |

| 19 | Alxan iska caabida adkaanta | ≥6H |

| 20 | Dib u dhaca ololka | 94V-0 |

| 21 | Xakamaynta caqabada | ± 5% |

Waxaan samaynaa prototype loox wareegyada PCB oo leh 15 sano oo waayo-aragnimo ah xirfadeena

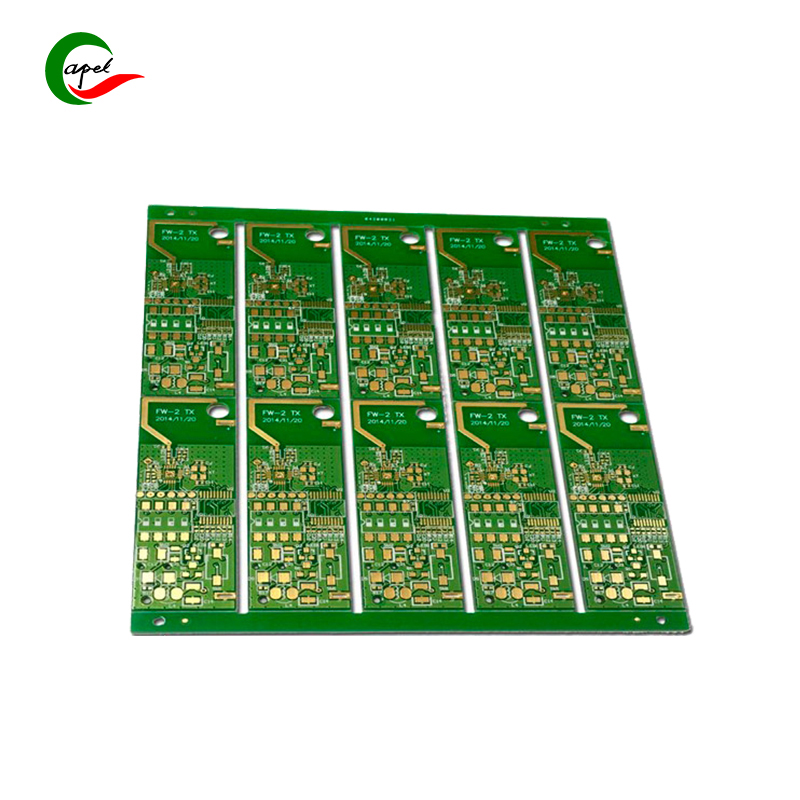

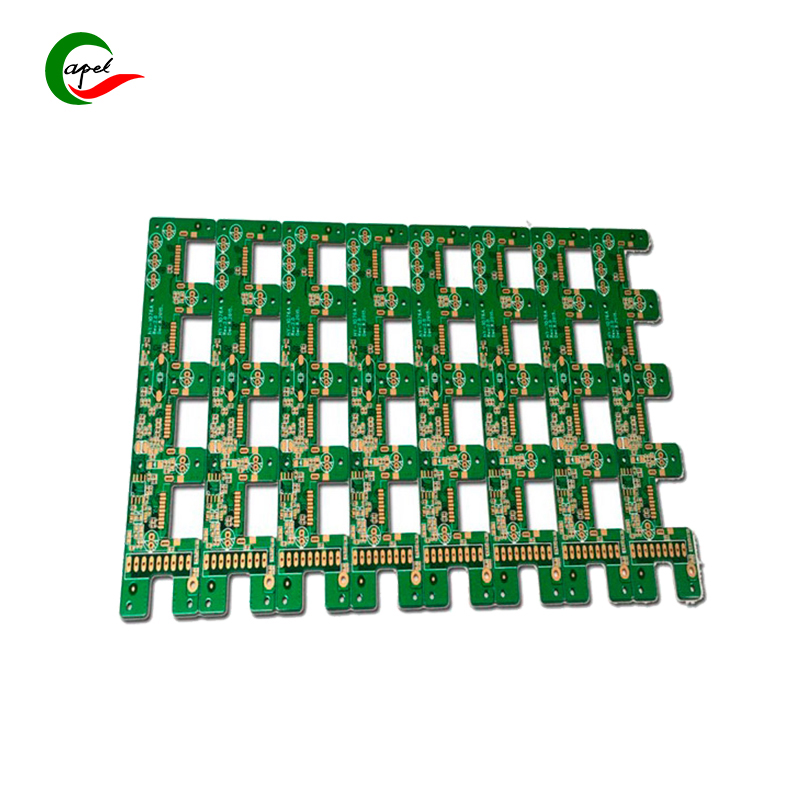

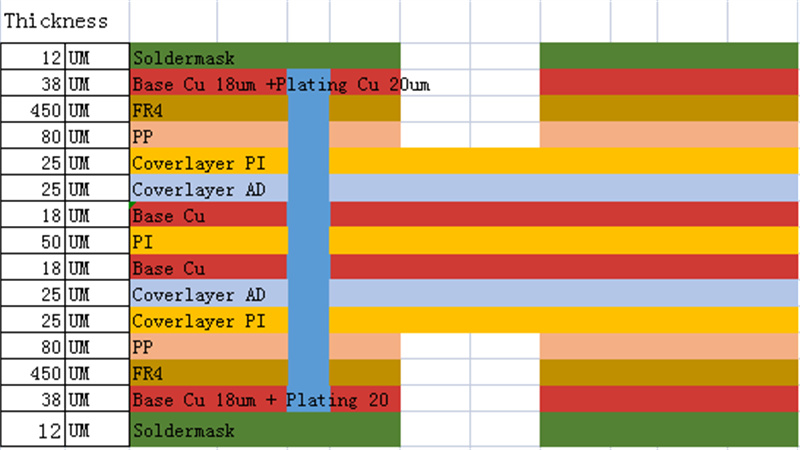

4 lakab Flex-Rigid Boards

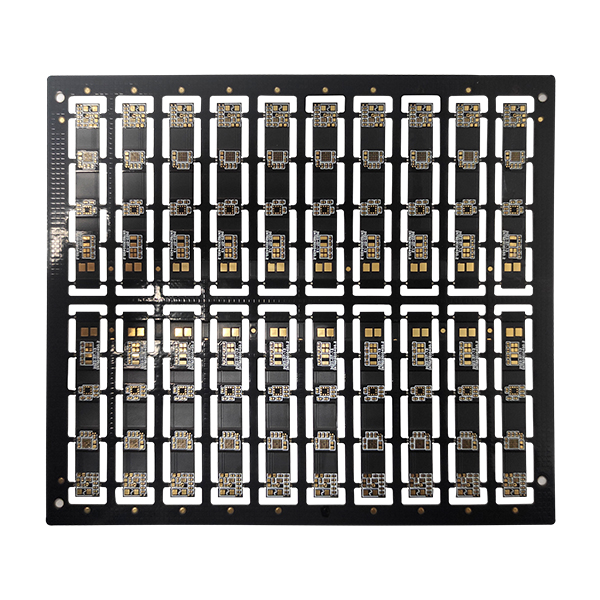

8 PCB-yada adag-Flex

8 lakab HDI PCBs

Qalabka Imtixaanka iyo Baaritaanka

Tijaabada Microscope

Kormeerka AOI

Tijaabada 2D

Tijaabada Impedance

Tijaabada RoHS

Baadhitaanka Duulaya

Tijaabada Horizontal

Laacidda Teste

Adeegga tusaalaha looxyada wareegyada ee PCB-ga

. Bixi taageero farsamo iibka ka hor iyo iibinta ka dib;

. Caadiyan ilaa 40 lakab, 1-2maalmood si degdeg ah u rogi kara wax-soo-saar la isku halayn karo, Iibka Qaybaha, Golaha SMT;

. U adeega labada Aaladaha Caafimaadka, Xakamaynta Warshadaha, Baabuurta, Duulista, Amniga, IOT, UAV, Isgaadhsiinta iwm.

. Kooxahayada injineerada iyo cilmi-baarayaasha waxay u heellan yihiin inay buuxiyaan shuruudahaaga si sax ah oo xirfad leh.

Sida loo doorto soo-saare khibrad leh oo xooggan si loo caddeeyo looxyada wareegga 6-lakabka ah.

1. Tixraac ereyga-afka iyo qiimaynta: Faham qiimaynta macaamiisha kale iyo ereyga-af-afka ee ku saabsan soo saaraha.

Macluumaadka laxidhiidha waxaa lagu heli karaa raadinta golayaasha onlineka ah, warbaahinta bulshada ama goobaha xirfadeed ee dib u eegista iyo jawaab celinta. Raadi kuwa leh sumcad adag iyo sannado khibrad leh.

2. Khibrad iyo khibrad: Hubi in soo-saaruhu uu leeyahay khibrad qani ah iyo khibrad xagga soo saarista looxyada wareegga 6-lakabka ah.

Baro taariikhdooda iyo taariikhdooda, oo ay ku jiraan muddada ay ku jireen warshadaha iyo tirada mashaariicda ay dhammeeyeen.

3. Awoodaha farsamada iyo qalabka: Hubi in soo-saaruhu uu leeyahay qalab horumarsan iyo tignoolajiyada lagu soo saaro looxyada wareegga 6-lakabka ah.

Baro awoodahooda si ay u soo saaraan looxyo adag iyo shirar cufan oo sarreeya si loo hubiyo inay buuxin karaan shuruudahaaga.

4. Xakamaynta tayada: Faham nidaamka xakamaynta tayada saaraha iyo habka. Miyay leeyihiin heerarka xakamaynta tayada adag iyo qalabka tijaabada saxda ah si loo hubiyo tayada badeecada, sida in la hirgaliyo nidaamka maaraynta tayada ISO 9001.

5. Kalsoonida iyo gaarsiinta: Qiimee kalsoonida alaab-qeybiyaha iyo gaarsiinta Ma awoodaan in ay mashruucyada ku dhamaystiraan waqtigii loogu talagalay oo ay bixiyaan wakhtiyo diritaan sax ah. Weydii haddii ay haystaan qorshe gurmad degdeg ah haddii ay dhacdo dib u dhac ama dhacdooyin lama filaan ah.

6. La hadal macmiisha jira: Haddii ay suurtagal tahay, la hadal macaamiisha jira ee alaab-qeybiyaha. Baro khibradooda iskaashi iyo ku qanacsanaanta, iyo sidoo kale dabeecadda shaqo ee soo saaraha iyo xawaaraha jawaabta.

7. Waraysi ama la xidhiidh warshadeeyayaasha: samee waraysiyo ama la xidhiidh wax-soosaarayaasha iman kara, oo weydii wax ku saabsan shuruudaha caddaynta iyo shuruudaha farsamada. U fiirso haddii jawaabahoodu iyo sharraxaadkoodu yihiin kuwo sax ah, xirfad leh, iyo kuwo lagu qanci karo, si aad u qiimeyso inay leeyihiin khibradda iyo xoogga aad u baahan tahay.

8. Qiimaha iyo adeegga: Ugu dambeyntii, tixgeli qiimaha iyo adeegga iibka ka dib si dhammaystiran. Hubi in qiimuhu yahay mid macquul ah oo bixi taageerada saxda ah ee iibka ka dib, sida la talinta farsamada, raadinta wax soo saarka iyo xalinta dhibaatada, iwm.

Habka caddaynta ee looxyada wareegga PCB ee lakabka 6 ah

1. Nashqad jaantuska jaantuska wareegga iyo qaabaynta: marka hore naqshadee jaantuska jaantuska wareegga iyo qaabaynta iyadoo loo eegayo shuruudaha naqshadaynta wareegga. Tani waa tallaabo muhiim ah oo lagu go'aaminayo cabbirrada guddiga, xeerarka dariiqa, meelaynta qalabka, iyo in ka badan.

2. Samee faylalka guddiga wareegyada: Isticmaal software naqshadeynta PCB si aad ugu beddesho schematics wareegga iyo qaabeynta faylalka guddiga wareegga.

Faylashaas sida caadiga ah waxaa ku jira faylalka Gerber, faylalka laydhka, faylasha alxanka, iwm.

3. Xaqiiji naqshadeynta: Ka hor inta aan la soo saarin guddiga wareegga, naqshadeynta wareegga waa la xaqiijiyaa. Hubi in nakhshadeynta guddigaagu ay xor ka tahay khaladaadka iyo arrimaha wax soo saarka adiga oo samaynaya jilidda wareegga iyo falanqaynta DFM (Naqshadaynta Wax-soosaarka).

4. Gudbi dalab: U soo gudbi dukumeentiyada guddiga iyo shuruudaha wax soo saarka ee u dhigma soo saaraha guddiga. Caadi ahaan waa lagama maarmaan in la bixiyo qaabka faylka, qalabka wareegga wareegga, tirada lakabyada, shuruudaha suufka, midabka maaskarada alxanka, shuruudaha shaashadda xariirta, shuruudaha nidaamka, iwm.

5. Manufacture board circuit: Saaraha guddida wareegyadu waxay soo saartaa si waafaqsan dukumentiyada la bixiyay.

Tan waxaa ka mid ah isticmaalka filimada khafiifka ah si loo abuuro qaabab looxa wareegga daabacan, kiimikaad etching ama makiinad si meesha looga saaro lakabyada naxaasta aan la rabin, daloolista, naxaasta ku dahaadhaysa, dul-kordhinta (pads, alxanka, silkscreen), dicing iyo hababka kale.

6. Samee tijaabada shaqada: Ku samee tijaabada shaqaynta sabuuradda la soo saaray si aad u hubiso hawshiisa caadiga ah.

7. Isku-dubbaridi guddida wareegga: ku dheji guddiga wareegga qalabka u dhigma ee tijaabada shaqaynta ama codsiga la taaban karo.

8. Qiimee natiijooyinka caddaynta: Ka dib markaad hesho guddiga wareegga caddaynta, samee qiimeyn dhamaystiran.

Hubi in muuqaalka iyo cabbirka guddiga wareeggu ay buuxinayaan shuruudaha, hubi suufka iyo tayada alxanka, oo tijaabi in waxqabadka iyo shaqada guddiga wareeggu ay yihiin kuwo caadi ah.

9. Wax ka beddelka iyo hagaajinta: Samee wax ka beddelka lagama maarmaanka ah iyo hagaajinta sida waafaqsan natiijooyinka qiimaynta.

Haddii guddiga wareegga la ogaado inuu leeyahay dhibaatooyin ama u baahan yahay in la hagaajiyo, faylasha naqshadeynta ayaa loo beddeli karaa si waafaqsan.

10. Dib-u-xaqiijinta: Haddii guddiga wareeggu leeyahay qadar badan oo wax ka beddel ah ama dhowr jeer ayaa loo baahan yahay, dib-u-celin ayaa la samayn karaa.

Ku soo celi habka hore, u gudbi faylka warshadda si loo soo saaro mar labaad, oo qiimee oo mar kale dib u eeg.

11. Wax-soo-saar ballaaran: Marka naqshadeynta iyo waxqabadka guddiga wareeggu ay yihiin kuwo lagu qanco, wax soo saarka ballaaran ayaa la fulin karaa. Wax-soo-saarayaashu waxay soo saaraan iyadoo la raacayo faylalka naqshadaynta kama dambaysta ah, waxayna soo saaraan tiro badan oo loox wareeg ah si ay u siiyaan macaamiisha.

12. La soco oo maamul silsiladda sahayda: Aad bay muhiim u tahay in la daba-galo lana maareeyo silsiladda sahayda inta lagu jiro hannaanka caddaynta iyo wax-soo-saarka tirada badan.

Ballanqaadka sahayda agabka, cusboonaysii horumarka wax-soo-saarka, habaynta saadka, iwm., oo hubi in wakhtiga loogu talo galay ee looxyada wareegyada.