Looxyada Wareegga ee Laba-dhinac ah ee Soo saaraha Pcb Prototype

Kartida Habka PCB

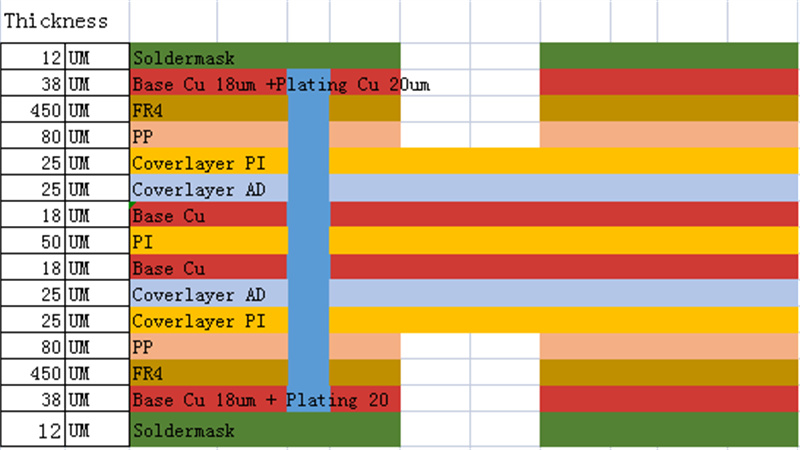

| Maya | Mashruuca | Tilmaamayaasha farsamada |

| 1 | Lakabka | 1 - 60 (lakab) |

| 2 | Meesha ugu sarraysa | 545 x 622 mm |

| 3 | Dhumucnaanta ugu yar | 4 (lakab) 0.40mm |

| 6 (lakab) 0.60mm | ||

| 8 (lakab) 0.8mm | ||

| 10 (lakab) 1.0mm | ||

| 4 | Balaadhka khadka ugu yar | 0.0762mm |

| 5 | Kala dheeraynta ugu yar | 0.0762mm |

| 6 | Daloollada ugu yar ee farsamada | 0.15mm |

| 7 | Dhumucdiisuna waxay tahay derbi dalool | 0.015mm |

| 8 | Dulqaadka daloolka birta ah | ±0.05mm |

| 9 | Dulqaad aan bir lahayn | ± 0.025mm |

| 10 | Dulqaadashada | ±0.05mm |

| 11 | Dulqaadka cabbirka | ± 0.076mm |

| 12 | Buundada alxanka ugu yar | 0.08mm |

| 13 | Iska caabin dahaarka | 1E+12Ω (caadi) |

| 14 | Saamiga dhumucda saxanka | 1:10 |

| 15 | Naxdinta kulaylka | 288 ℃ (4 jeer 10 ilbiriqsi gudahood) |

| 16 | Qallooc iyo qaloocsanaan | ≤0.7% |

| 17 | Awood ka-hortagga korontada | 1.3KV/mm |

| 18 | Xoogga ka-hortagga | 1.4N/mm |

| 19 | Alxan iska caabiso adkaanta | ≥6H |

| 20 | Dib u dhaca ololka | 94V-0 |

| 21 | Xakamaynta caqabada | ± 5% |

Waxaanu samaynaa Gudiyada Wareega Prototyping annagoo khibrad 15 sano u leh xirfadayada

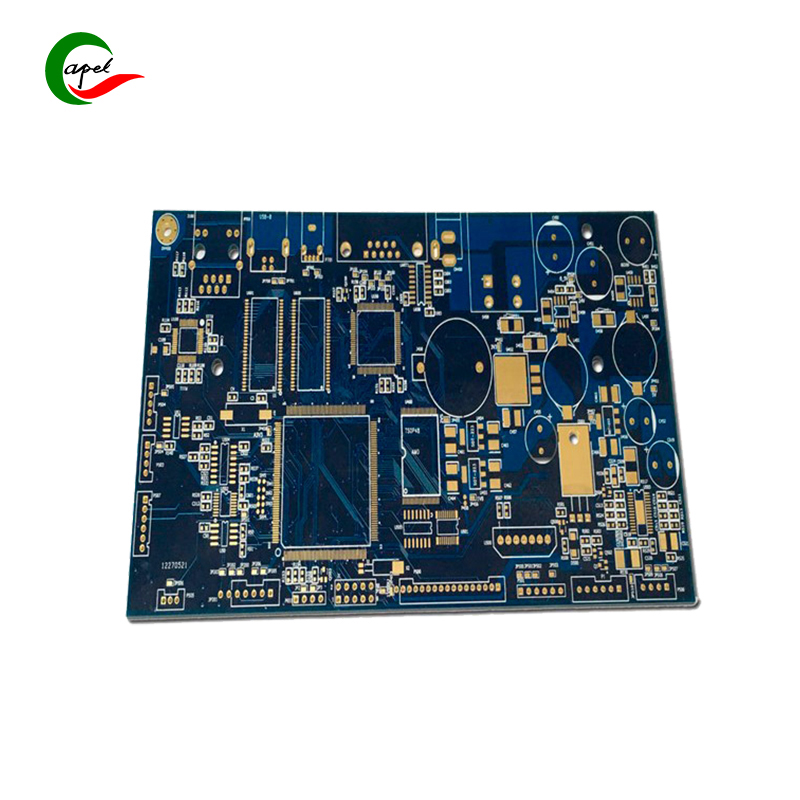

4 lakab Flex-Rigid Boards

8 PCB-yada adag-Flex

8 lakab HDI Printed Wareegtada

Qalabka Imtixaanka iyo Kormeerka

Tijaabada Microscope

Kormeerka AOI

Tijaabada 2D

Tijaabada Impedance

Tijaabada RoHS

Baadhitaanka Duulaya

Tijaabada Horizontal

Laacidda Teste

Adeegga wax-soo-saarka ee looxyada wareegyada

.Bixi taageero farsamo ka hor iibka iyo iibinta ka dib;

.Caadiyan ilaa 40 lakab, 1-2maalmood si degdeg ah u rogi kara wax-soo-saar la isku halayn karo, Iibka Qaybaha, Golaha SMT;

.U adeegta labada Aaladaha Caafimaadka, Xakamaynta Warshadaha, Baabuurta, Duulista, Elektarooniga Macmiilka, IOT, UAV, Isgaadhsiinta iwm.

.Kooxahayada injineerada iyo cilmi-baarayaasha waxay u heellan yihiin inay buuxiyaan shuruudahaaga si sax ah oo xirfad leh.

Sidee loo soo saaraa Guddi-wareeg Laba-dhinac ah oo tayo sare leh?

1. Nakhshad sabuuradda: Isticmaal kombuyuutar-kaalmaynta design (CAD) software si aad u abuurto qaabka looxa.Hubi in naqshadu ay buuxisay dhammaan shuruudaha korontada iyo farsamada, oo ay ku jiraan balladhka raadraaca, kala dheeraynta, iyo meelaynta qaybaha.Tixgeli arrimo ay ka mid yihiin daacadnimada calaamadda, qaybinta awoodda, iyo maaraynta kulaylka.

2. Baahinta iyo tijaabinta: Kahor soo saarista tirada badan, waxaa muhiim ah in la sameeyo guddi tusaale u ah si loo ansixiyo naqshadda iyo habka wax soo saarka.Si fiican u tijaabi noocyada shaqada, waxqabadka korantada, iyo ku haboonaanta makaanikada si aad u aqoonsato wixii arrimo ama horumarin kara

3. Xulashada Qalabka: Dooro shay tayo sare leh oo ku habboon shuruudahaaga gaarka ah.Doorashooyinka walxaha caadiga ah waxaa ka mid ah FR-4 ama heerkul sare FR-4 ee substrate-ka, naxaasta raadadka wax-qabadka, iyo maaskaro alxan si loo ilaaliyo qaybaha.

4. Samee lakabka gudaha: Marka hore diyaari lakabka gudaha ee looxa, kaas oo ku lug leh dhowr tallaabo:

a.Nadiifi oo qallaji lakabka maarta leh.

b.Codso filim qallalan oo sawir dhuuban oo khafiif ah oogada naxaasta ah.

c.Filimku wuxuu soo bandhigay iftiinka ultraviolet (UV) iyada oo loo marayo qalab sawir leh oo ka kooban qaabka wareegga la rabo.

d.Filimku wuxuu soo saaray si meesha looga saaro meelaha aan la daboolin, isaga oo ka tagaya qaabka wareegga.

e.Etch daboolka naxaasta si ay meesha uga saarto walxaha xad-dhaafka ah ee ka tagaya kaliya raadadka iyo suufka la rabo.

F. Ka eeg lakabka gudaha wixii cillad ah ama ka leexashada naqshadeynta.

5. Laminates: Lakabyada gudaha waxaa lagu soo ururiyaa prepreg ee saxaafadda.Kuleylka iyo cadaadiska ayaa lagu dabaqaa si loo xiro lakabyada oo loo sameeyo guddi xooggan.Hubi in lakabyada gudaha ay si sax ah u siman yihiin oo loo diwaan gashan yahay si looga hortago wax khaldan.

6. Qodista: Isticmaal mishiinka qodista saxda ah si aad godadka u qoddo qaybaha iyo isku xidhka.Xajmiyada kala duwan ee qashin-qubka ayaa loo isticmaalaa iyadoo loo eegayo shuruudo gaar ah.Hubi saxnaanta meesha godka iyo dhexroorka.

Sidee loo soo saaraa Guddi-wareeg Laba-dhinac ah oo tayo sare leh?

7. Dheejinta Naxaasta aan Koronto lahayn: Marso lakab khafiif ah oo naxaas ah dhammaan sagxadaha gudaha ee bannaan.Talaabadani waxay xaqiijinaysaa dhaqdhaqaaqa saxda ah waxayna fududaynaysaa habka dhejinta ee talaabooyinka xiga.

8. Sawirka lakabka sare: Si la mid ah habka lakabka gudaha, filim qallalan oo sawir leh ayaa lagu dahaadhay lakabka naxaasta ee dibadda.

U soo bandhig nalka UV iyada oo loo marayo qalabka sawirka sare oo samee filimka si aad u muujiso qaabka wareegga.

9. Etching lakabka sare: Ka saar naxaasta aan loo baahnayn ee dusha sare, adigoo ka tagaya raadadka iyo suufka loo baahan yahay.

Ka hubi lakabka sare wixii cillado ah ama weecsan.

10. Maaskarada Alxanka iyo Daabacaadda Halyeeyga: Codso maaskaro alxanka si aad u ilaaliso raadadka naxaasta iyo suufka marka aad ka baxayso meel loogu talagalay kordhinta qaybaha.Ku daabac halyeeyada iyo calamadaha lakabyada sare iyo hoose si aad u muujiso meesha ay ka kooban tahay, polarity, iyo macluumaadka kale.

11. Diyaarinta Dusha: Diyaarinta dusha sare ayaa la mariyaa si loo ilaaliyo dusha naxaasta ah ee ka soo baxa oksaydheynta iyo si loo helo dusha sare ee la iibin karo.Ikhtiyaarada waxaa ka mid ah heerka hawo kulul (HASL), dahabka nikkel immersion (ENIG), ama dhamaystir kale oo horumarsan.

12. Jideynta iyo Samaynta: Panelyada PCB-ga waxaa loo kala gooyaa loox gaar ah iyadoo la isticmaalayo mashiinka dariiqa ama habka V-scribing.

Hubi in cidhifyadu nadiif yihiin oo cabbiradu ay sax yihiin.

13. Tijaabada Korontada: Samee tijaabinta korantada sida tijaabinta joogtada ah, cabirada iska caabinta, iyo hubinta go'doominta si loo hubiyo shaqada iyo daacadnimada looxyada la sameeyay.

14. Xakamaynta Tayada iyo Kormeerka: Looxyada la dhammeeyay ayaa si fiican loo eegaa cillad kasta oo wax soo saar ah sida surwaal gaaban, fur-furan, qallafsanaan, ama cilladaha dusha sare.Hirgelinta hababka xakamaynta tayada si loo hubiyo u hoggaansanaanta xeerarka iyo heerarka.

15. Baakaynta iyo dhoofinta: Ka dib marka guddigu dhaafo kormeerka tayada, si ammaan ah ayaa loo buuxiyaa si looga hortago burbur inta lagu jiro dhoofinta.

Hubi calaamadaynta saxda ah iyo dukumentiyada si sax ah loola socdo loona aqoonsado looxyada.