Markaad dooranayso habka daaweynta dusha (sida dahabka immersion, OSP, iwm.) PCB-gaaga 3-lakabka ah, waxay noqon kartaa hawl adag.Maadaama ay jiraan doorashooyin badan, waa lagama maarmaan in la doorto habka daaweynta dusha ugu habboon si loo buuxiyo shuruudahaaga gaarka ah.In this post blog, waxaan ka wada hadli doonaa sida loo doorto daaweynta dusha ugu fiican ee 3-Lakabka PCB, muujinaya khibrad Capel, oo ah shirkad caan ku ah ay gacanta ku tayada sare iyo horumarinta PCB wax soo saarka.

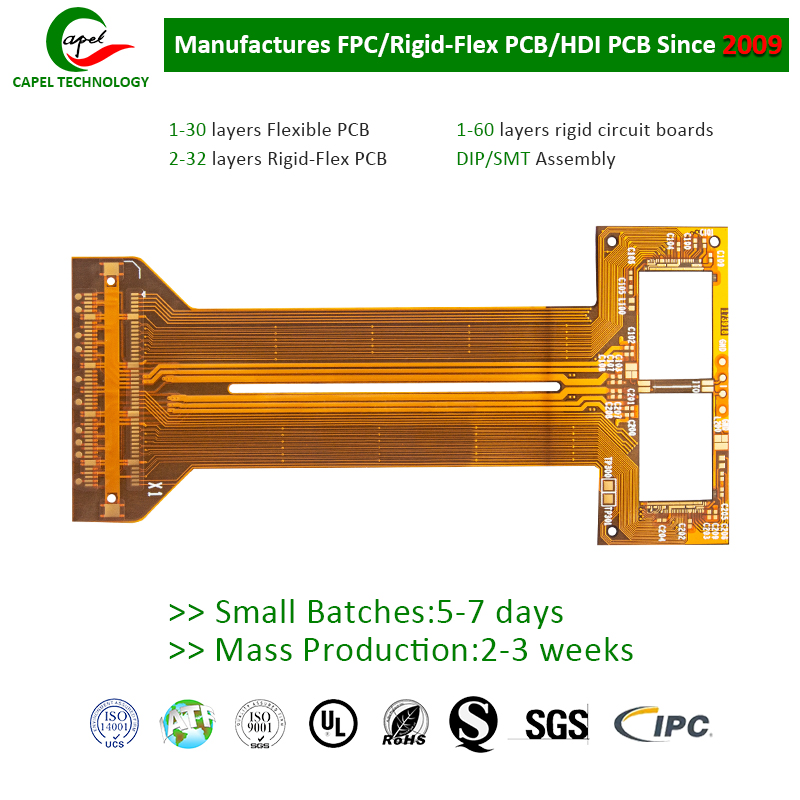

Capel waxay caan ku tahay PCB-yada dabacsan, PCB-yada dabacsan iyo HDI PCBs.Shahaadooyinka la aqoonsan yahay iyo hannaan-socodyo kala duwan oo horumarsan oo PCB ah, Capel waxay isu dejisay sidii hoggaamiye warshadeed.Hadda aan si dhow u eegno arrimaha la tixgelinayo marka la dooranayo dhammayn dusha sare ee PCB-lakab ah.

1. Codsiga iyo deegaanka

Marka hore, waa muhiim in la go'aamiyo codsiga iyo deegaanka PCB-ga 3-lakabka ah.Nidaamyada daaweynta dusha kala duwan waxay bixiyaan heerar kala duwan oo ka hortagga daxalka, oksaydhka iyo arrimaha kale ee deegaanka.Tusaale ahaan, haddii PCB-gaagu uu la kulmo xaalado adag, sida qoyaan badan ama heerkul aad u daran, waxaa lagu talinayaa in aad doorato habka daawaynta dusha sare oo bixisa ilaalin la xoojiyey, sida dahab la geliyo.

2. Qiimaha iyo wakhtiga dhalmada

Dhinac kale oo muhiim ah in la tixgeliyo waa kharashka iyo wakhtiga hogaanka ee la xidhiidha hababka daaweynta dusha kala duwan.Qiimaha alaabta, shuruudaha shaqada iyo guud ahaan wakhtiga wax soo saarka ayaa ku kala duwan nidaamka kasta.Qodobadan waa in lagu qiimeeyaa miisaaniyadaada iyo wakhtiga mashruuca si loo gaadho go'aan xog ogaal ah.Khibradda Capel ee hababka wax soo saarka horumarsan waxay hubisaa xalalka kharash-ku-ool ah iyo waqtiga ku habboon baahidaada diyaarinta PCB-gaaga.

3. U Hogaansanaanta RoHS

RoHS (Xakamaynta Walxaha Khatarta ah) u hoggaansanaantu waa qodob muhiim ah, gaar ahaan haddii alaabtaadu tahay suuqa Yurub.Dawaynta dusha qaarkood waxa ku jiri kara walxo khatar ah oo ka sarreeya xadka RoHS.Waa muhiim in la doorto habka daawaynta dusha sare ee waafaqsan xeerarka RoHS.Ballanqaadka Capel ee ilaalinta tayada waxay hubisaa in habraaceeda daawaynta dusha sare ay waafaqsan yihiin RoHS, taasoo ku siinaysa niyadda maskaxda marka ay timaado u hoggaansanaanta.

4. Alxanka iyo xidhidhiyaha siliga

Alxanka iyo sifooyinka isku xidhka fiilada ee PCB waa tixgalin muhiim ah.Habka daaweynta dusha sare waa inuu xaqiijiyaa alxanka wanaagsan, taasoo keentay in lagu dhejiyo alxanka habboon inta lagu jiro kulanka.Intaa waxaa dheer, haddii naqshadda PCB-gaagu ay ku lug leedahay isku-xidhka siliga, habka daaweynta dusha sare waa inuu hagaajiyaa isku halaynta curaarta siliga.OSP (Organic Solderability Preservative) waa doorasho caan ah oo ay ugu wacan tahay alxanka wanaagsan iyo ku-xidhnaanta siliga.

5. Talo iyo taageero khabiir

Doorashada habka saxda ah ee daaweynta dusha sare ee PCB-gaaga 3-lakabka ah waxay noqon kartaa mid adag, gaar ahaan haddii aad ku cusub tahay wax soo saarka PCB.Raadinta talo khabiir iyo taageero shirkad la isku halayn karo sida Capel waxay ka dhigi kartaa habka go'aan qaadashada mid sahlan.Kooxda khibradda leh ee Capel ayaa ku hagi kara habka xulashada waxayna kugula talinayaan habka daaweynta dusha ugu habboon ee ku salaysan shuruudahaaga gaarka ah.

Marka la soo koobo, doorashada daaweynta dusha ugu habboon ee PCB-gaaga 3-lakabka ah ayaa muhiim u ah waxqabadka ugu wanaagsan iyo cimri dhererka.Waxyaabaha ay ka midka yihiin codsiga iyo deegaanka, kharashka iyo wakhtiga rasaasta, u hogaansanaanta RoHS, iibinta iyo xidhitaanka siliga waa in si taxadar leh loo qiimeeyaa.Xakamaynta tayada Capel, shahaadooyinka lahaanshaha leh iyo hababka wax soo saarka PCB ee horumarsan ayaa awood u siinaya inay buuxiso baahiyahaaga diyaarinta.La tasho khubarada Capel oo ka faa'iidayso aqoontooda iyo waayo-aragnimadooda warshadeed ee ballaaran.Maskaxda ku hay in hababka daaweynta dusha si taxadar leh loo doortay ay si weyn u saameyn karaan waxqabadka guud iyo cimri dhererka 3-lakabka PCB.

Waqtiga boostada: Seb-29-2023

Dib u noqo