Soo-saareyaasha PCB-yada Prototying-ka-badan ee Soo-saareyaal Degdeg ah U-rogista Guddiyada PCB

Kartida Habka PCB

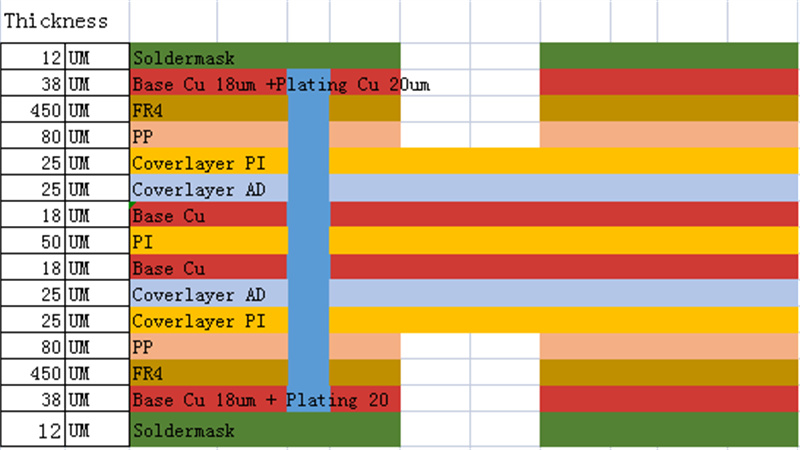

| Maya | Mashruuca | Tilmaamayaasha farsamada |

| 1 | Lakabka | 1 - 60 (lakab) |

| 2 | Meesha ugu sarraysa | 545 x 622 mm |

| 3 | Dhumucnaanta ugu yar | 4 (lakab) 0.40mm |

| 6 (lakab) 0.60mm | ||

| 8 (lakab) 0.8mm | ||

| 10 (lakab) 1.0mm | ||

| 4 | Balaadhka khadka ugu yar | 0.0762mm |

| 5 | Kala dheeraynta ugu yar | 0.0762mm |

| 6 | Daloollada ugu yar ee farsamada | 0.15mm |

| 7 | Dhumucdiisuna waxay tahay derbi dalool | 0.015mm |

| 8 | Dulqaadka daloolka birta ah | ±0.05mm |

| 9 | Dulqaad aan bir lahayn | ± 0.025mm |

| 10 | Dulqaadashada | ±0.05mm |

| 11 | Dulqaadka cabbirka | ± 0.076mm |

| 12 | Buundada alxanka ugu yar | 0.08mm |

| 13 | Iska caabin dahaarka | 1E+12Ω (caadi) |

| 14 | Saamiga dhumucda saxanka | 1:10 |

| 15 | Naxdinta kulaylka | 288 ℃ (4 jeer 10 ilbiriqsi gudahood) |

| 16 | Qallooc iyo qaloocsanaan | ≤0.7% |

| 17 | Awood ka-hortagga korontada | 1.3KV/mm |

| 18 | Xoogga ka-hortagga | 1.4N/mm |

| 19 | Alxan iska caabida adkaanta | ≥6H |

| 20 | Dib u dhaca ololka | 94V-0 |

| 21 | Xakamaynta caqabada | ± 5% |

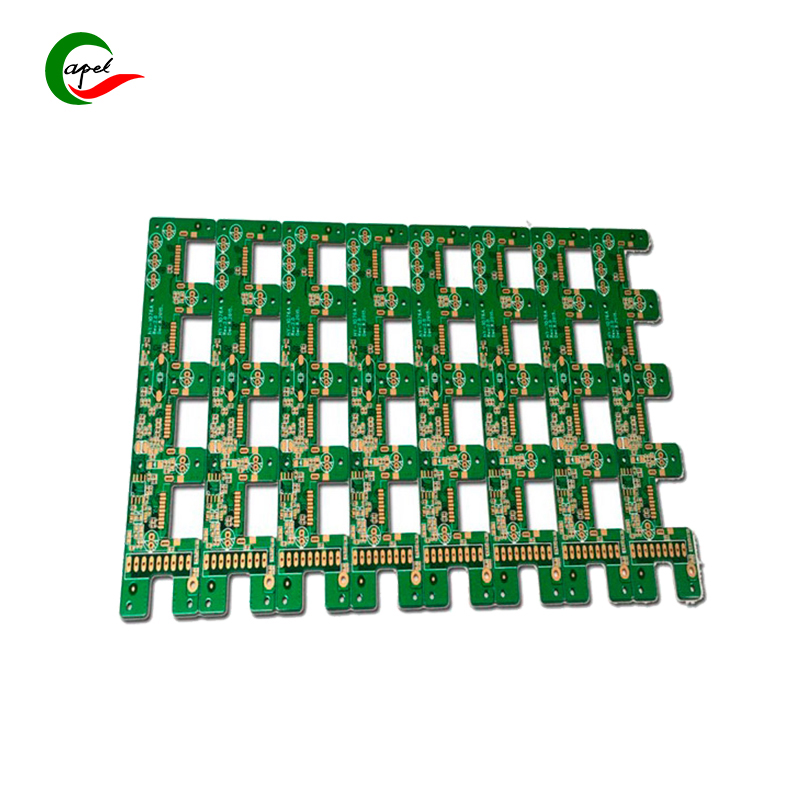

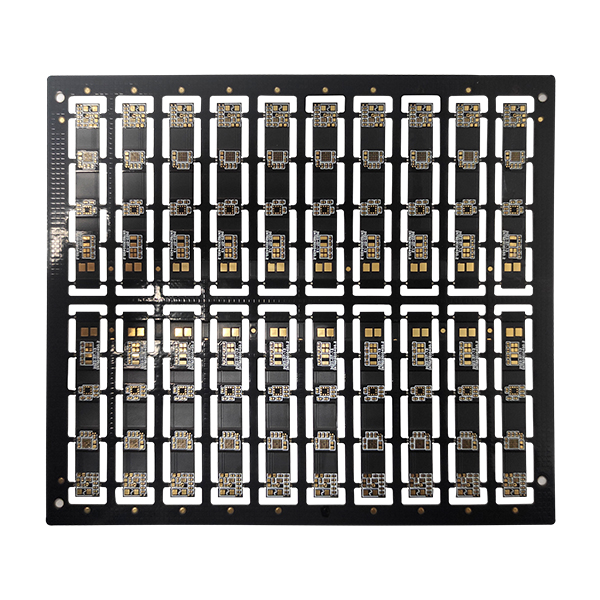

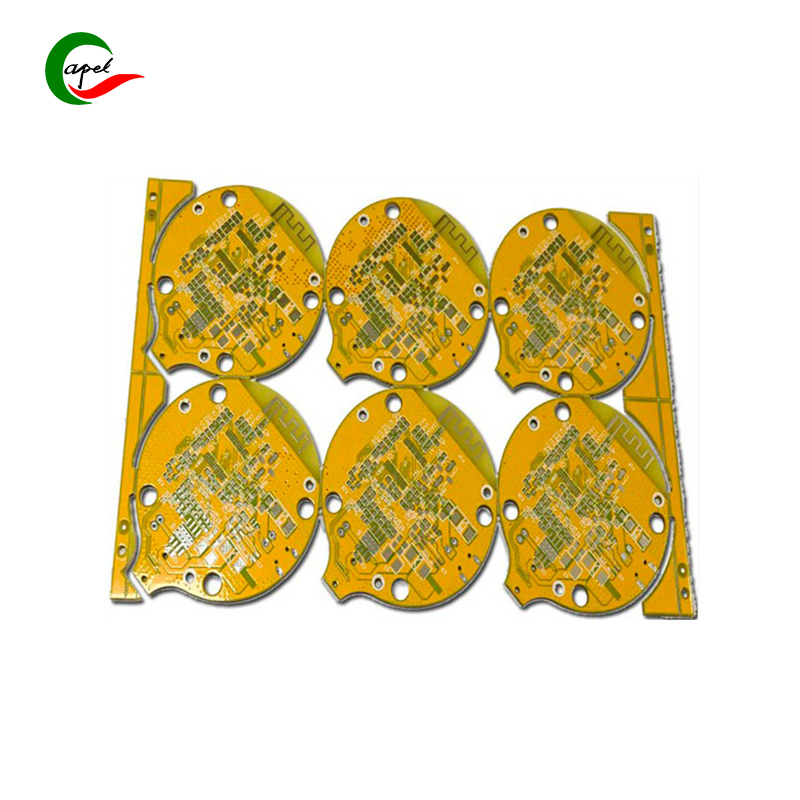

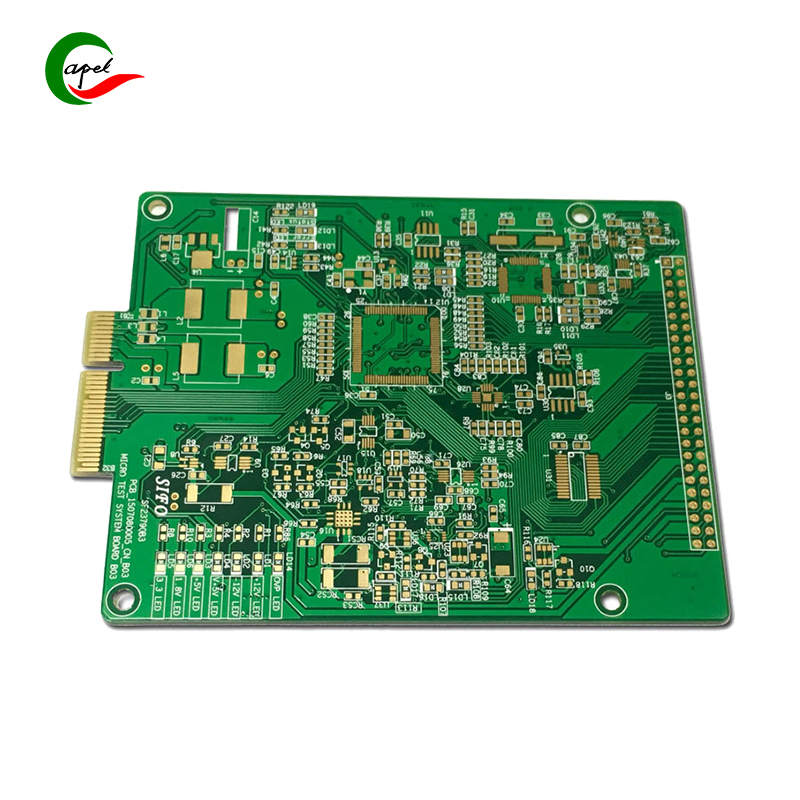

Waxaan samaynaa qaabaynta PCB-yada Multilayer oo leh khibrad 15 sano ah oo ku saabsan xirfadayada

4 lakab Flex-Rigid Boards

8 PCB-yada adag-Flex

8 lakab HDI PCBs

Qalabka Imtixaanka iyo Baaritaanka

Tijaabada Microscope

Kormeerka AOI

Tijaabada 2D

Tijaabada Impedance

Tijaabada RoHS

Baadhitaanka Duulaya

Tijaabada Horizontal

Laacidda Teste

Adeegeena Multilayer PCBs-ka Adeegga wax-soo-saarka

. Bixi taageero farsamo iibka ka hor iyo iibinta ka dib;

. Caadiyan ilaa 40 lakab, 1-2maalmood si degdeg ah u rogi kara wax-soo-saar la isku halayn karo, Iibka Qaybaha, Golaha SMT;

. U adeegta labada Aaladaha Caafimaadka, Xakamaynta Warshadaha, Baabuurta, Duulista, Elektarooniga Macmiilka, IOT, UAV, Isgaadhsiinta iwm.

. Kooxahayada injineerada iyo cilmi-baarayaasha waxay u heellan yihiin inay buuxiyaan shuruudahaaga si sax ah oo xirfad leh.

Multilayer PCB waxay bixisaa taageero farsamo oo horumarsan oo ku saabsan goobta baabuurta

1. Nidaamka madadaalada baabuurta: PCB-lakab badan ayaa taageeri kara hawlo badan oo maqal ah, muuqaal ah iyo isgaarsiin wireless, sidaas darteed bixinta khibrad madadaalo baabuur oo hodan ah. Waxay dejin kartaa lakabyo wareeg ah oo badan, waxay buuxin kartaa baahiyo kala duwan oo maqal iyo muuqaal ah, waxayna taageertaa gudbinta xawaaraha sare iyo hawlaha isku xirka wireless, sida Bluetooth, Wi-Fi, GPS, iwm.

2. Nidaamka Badbaadada: PCB-da lakabyo badan ayaa bixin kara waxqabadka badbaadada sare iyo isku halaynta, waxaana lagu dabaqaa baabuurta firfircoon iyo nidaamyada badbaadada. Waxay isku dari kartaa dareemayaasha kala duwan, unugyada kantaroolka iyo qaybaha isgaarsiinta si loo xaqiijiyo shaqooyinka sida digniinta isku dhaca, bareega tooska ah, wadista caqliga leh, iyo tuugada ka hortagga. Naqshadeynta PCB-da lakabyo badan waxay hubisaa isgaarsiin degdeg ah, sax ah oo la isku halayn karo iyo iskudubarid ka dhexeeya qaybaha nidaamka badbaadada ee kala duwan.

3. Nidaamka caawinta darawalnimada: PCB-da lakabka badan waxay ku siin kartaa hab-socodka calaamadaha saxda ah ee saxda ah iyo gudbinta xogta degdega ah ee hababka caawinta wadista, sida baarkinka tooska ah, ogaanshaha indho la'aanta, xakamaynta safarka la qabsiga iyo hababka gargaarka haynta haadka, iwm.

Nidaamyadani waxay u baahan yihiin habaynta calaamadaha saxda ah iyo wareejinta xogta degdegga ah. Iyo garashada waqtiga iyo awoodaha xukunka, iyo taageerada farsamada ee PCB-da lakabyada badan ayaa buuxin kara shuruudahan.

4. Nidaamka maaraynta matoorka: Nidaamka maaraynta mishiinka wuxuu isticmaali karaa PCB-da lakabyo badan si loo xaqiijiyo xakamaynta saxda ah iyo la socodka matoorka.

Waxay isku dari kartaa dareemayaasha kala duwan, hawl-wadeennada iyo unugyada kantaroolka si ay ula socdaan oo ay u hagaajiyaan cabbirrada sida bixinta shidaalka, wakhtiga dabka iyo xakamaynta qiiqa matoorka si loo hagaajiyo waxtarka shidaalka loona yareeyo qiiqa qiiqa.

5. Nidaamka wadista korantada: PCB-da lakabyo badan ayaa bixiya taageero farsamo oo horumarsan oo loogu talagalay maareynta tamarta korantada iyo gudbinta awoodda baabuurta korontada iyo baabuurta isku-dhafka ah. Waxay taageeri kartaa gudbinta awoodda sare ee awoodda iyo xakamaynta oscillation, hagaajinta hufnaanta iyo isku halaynta nidaamka maaraynta batteriga, iyo in la hubiyo shaqada isku dubaridka ah ee qaybaha kala duwan ee nidaamka wadista korontada.

Looxyada wareegyada kala duwan ee goobta baabuurta FAQ

1. Baaxadda iyo miisaanka: Meesha baabuurka ku taal waa mid xaddidan, sidaas awgeed cabbirka iyo miisaanka looxa wareegga wareegga ah ayaa sidoo kale ah arrimo u baahan in la tixgeliyo. Looxyada aadka u weyn ama culus waxay xaddidi karaan naqshadeynta iyo waxqabadka baabuurka, sidaas darteed waxaa loo baahan yahay in la yareeyo xajmiga guddiga iyo miisaanka naqshadeynta iyadoo la ilaalinayo shaqeynta iyo shuruudaha waxqabadka.

2. Ka-hortagga gariirka iyo iska caabinta saameynta: Baabuurka waxaa lagu soo rogi doonaa gariir iyo saameyn kala duwan inta lagu jiro wadista, sidaas darteed guddiga wareegga badan wuxuu u baahan yahay inuu yeesho ka hortagga gariirka iyo iska caabbinta saameynta wanaagsan. Tani waxay u baahan tahay qaab-dhismeedka macquulka ah ee qaab dhismeedka taageerada guddiga wareegga iyo xulashada alaabta ku habboon si loo hubiyo in guddiga wareeggu uu weli si deggan ugu shaqeyn karo xaaladaha waddooyinka adag.

3. La qabsiga deegaanka: goobta shaqada ee baabuurtu waa mid adag oo la bedeli karo, looxyada wareegyada lakabyada badan waxay u baahan yihiin inay la qabsadaan xaaladaha deegaanka ee kala duwan, sida heerkulka sare, heerkulka hoose, qoyaanka, iwm. dooro alaabta leh iska caabin heerkul sare oo wanaagsan, iska caabin heerkul hooseeya iyo iska caabbinta qoyaanka, iyo Qaado tallaabooyin ilaalin oo u dhigma si aad u hubiso in guddiga wareeggu uu si kalsooni leh ugu shaqeyn karo deegaanno kala duwan.

4. Isku-waafajinta iyo naqshadeynta is-dhexgalka: Guddiyada wareegga-badanaa waxay u baahan yihiin inay la jaanqaadaan oo ay ku xiran yihiin qalabka iyo nidaamyada kale ee elektiroonigga ah, sidaas darteed naqshadeynta isugeynta iyo tijaabinta is-dhexgalka ayaa loo baahan yahay. Tan waxaa ka mid ah xulashada xirayaasha, u hoggaansanaanta heerarka interface, iyo hubinta xasilloonida calaamadaha interface iyo isku halaynta.

6. Baakadaha Chip-ka iyo barnaamijka: Baakadaha chip-ka iyo barnaamijka ayaa laga yaabaa inay ku lug yeeshaan looxyada wareegyada badan. Marka la naqshadeynayo, waxaa lagama maarmaan ah in la tixgeliyo qaabka xirmada iyo xajmiga chip, iyo sidoo kale interface iyo habka gubashada iyo barnaamijka. Tani waxay hubinaysaa in chip-ka loo habayn doono oo uu u shaqayn doono si sax ah oo la isku halleyn karo.